DESCRIPTION

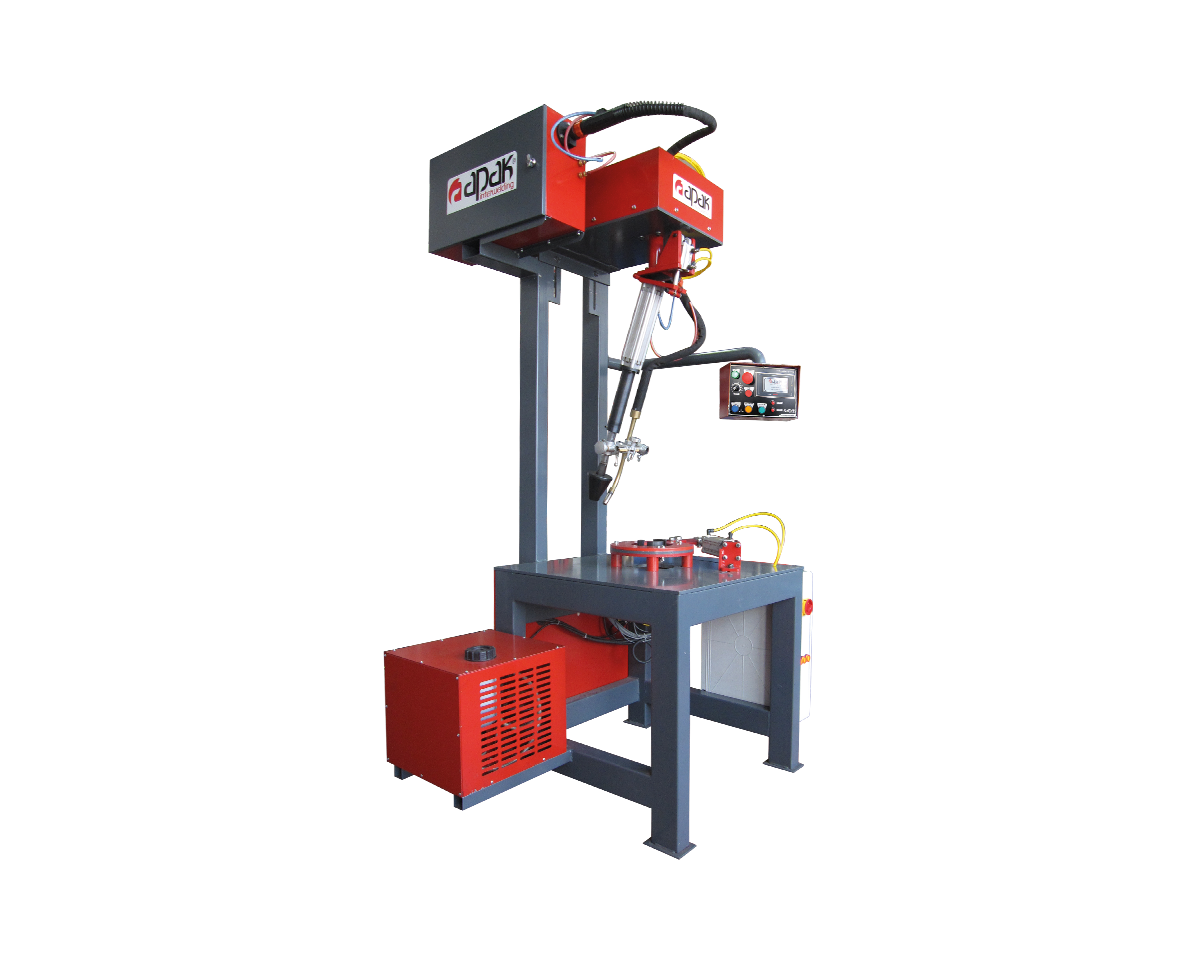

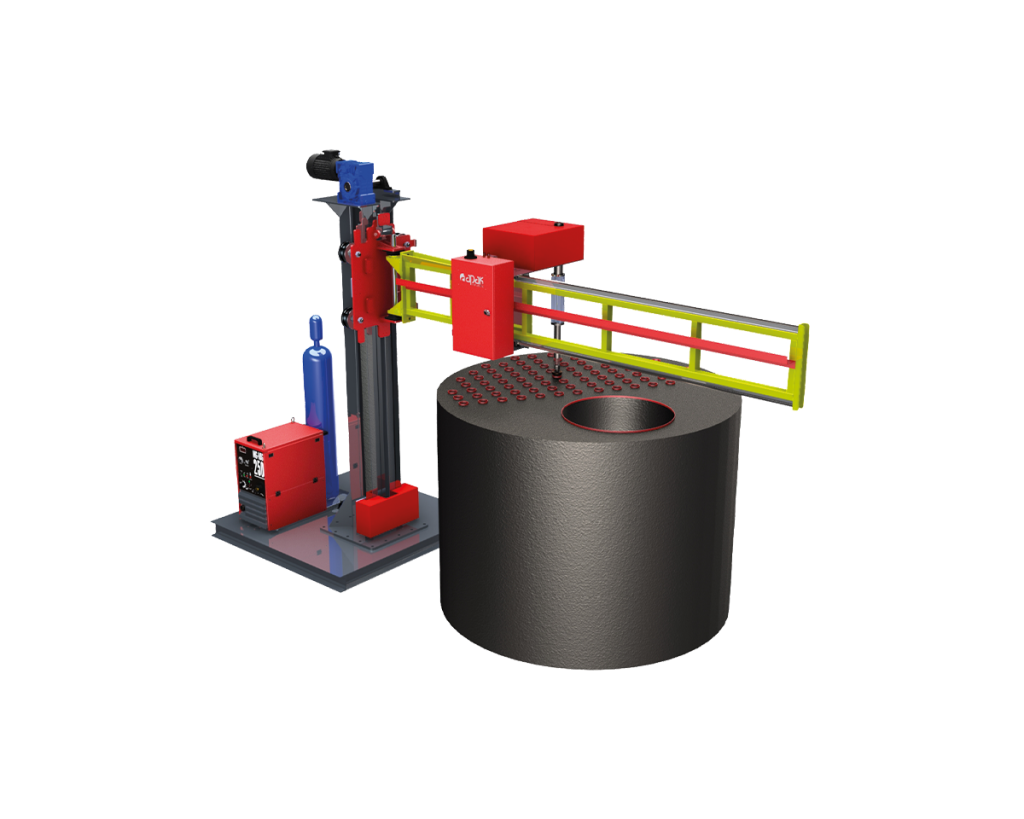

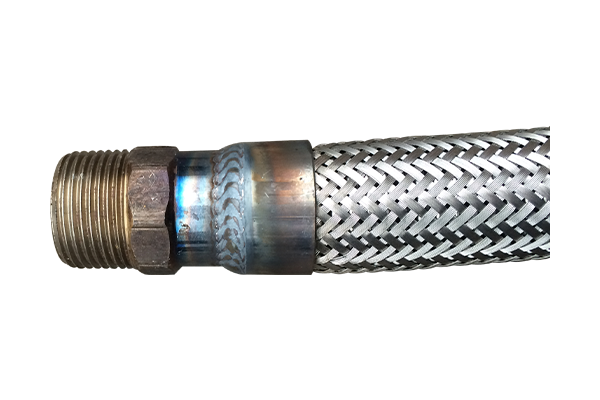

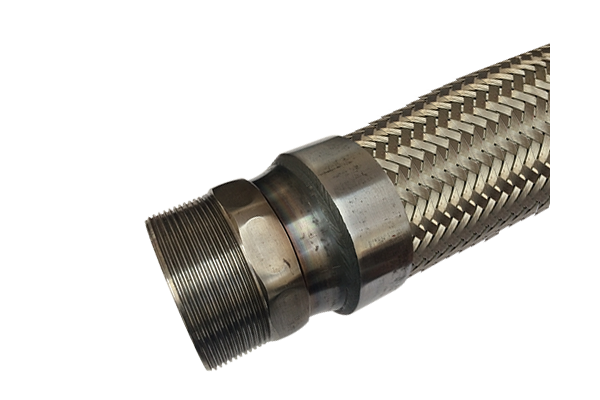

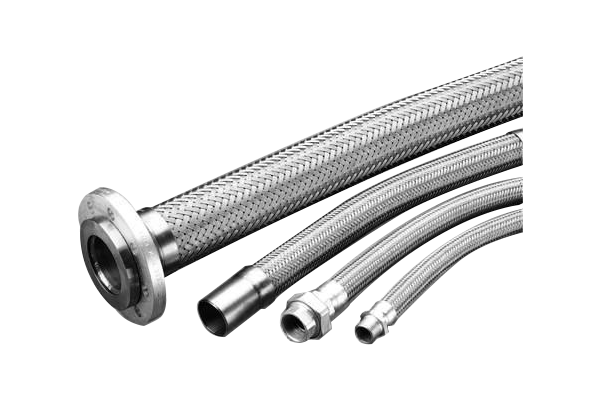

Flexible Metal Hose Welding Machine from Apak Interwelding is designed for butt welding of braided and non-braided flexible hoses. Therefore, it delivers excellent results for welding unions, elbows, and flanges in hose production. Moreover, the system minimizes operator dependency and reduces the need for highly qualified personnel, making it ideal for modern production facilities.

In addition, the machine helps prevent hose deformations that typically occur with conventional oxy-acetylene welding. As a result, manufacturers achieve more reliable and safer welds. Furthermore, the system supports both Oscillator GMAW (MIG/MAG) and wire-fed GTAW (TIG) welding methods, ensuring flexibility for different production requirements.

Another advantage of the Flexible Metal Hose Welding Machine is its operator-friendly design. Thus, it reduces fatigue during long welding cycles and ensures higher comfort for the workforce. Consequently, leakage problems are minimized, and consistent weld quality is maintained.

Additionally, the standard holding size of the system is suitable for 3/4″ to 1″ flexible hoses. However, it can also be redesigned and manufactured to handle different hose diameters, providing customized solutions for diverse applications.

In conclusion, the Flexible Metal Hose Welding Machine is more than a welding device. Indeed, it is a complete production solution that improves quality, prevents leakage issues, and increases production capacity. Therefore, manufacturers investing in this machine benefit from durability, flexibility, and reliable performance in every stage of hose welding operations.

- Steam transport pipes

- Compressed air pipes

- Hot oil pipes

- Heating, ventilation, and air conditioning systems

- Chemical and petrochemical plants

- Shipbuilding and drilling facilities

- Oil and gas processes

- Aircraft industry

- Food and chemical enterprises

- GMAW (MIG/MAG)

- GTAW (TIG)

FEATURES & BENEFITS

Application Examples

Engineered for productivity.

- At least four times faster than manual welding

- Perfect weld seams

- No specialist welder is required.

- Repeatable welding precision

- Easy-to-use interface

Standard Features

- Flexible hose holding capacity in 3/4″ – 1″ size range

- Pneumatic centering

- Refrigerant gas system

- GMAW (MIG/MAG) welding system

- PLC control system

- Touchscreen LCD control panel

Optional Features

- Welding oscillator

- GTAW (TIG) welding system

- Wire feed system for GTAW (TIG) welding

- Lighting

DOCUMENTS

Flexible Metal Hose Welding Machine

English Brochure

Automatisches Orbitalschweißen

Deutsche Broschüre

MEDIA

Our team of experts will help you in all situations

You tell about your production problems, we will offer solutions.

01

Tell us about your problems and your goals in manufacturing.

02

We will contact you and provide detailed negotiations.

03

Let us offer you our specially prepared solution suggestions.