DESCRIPTION

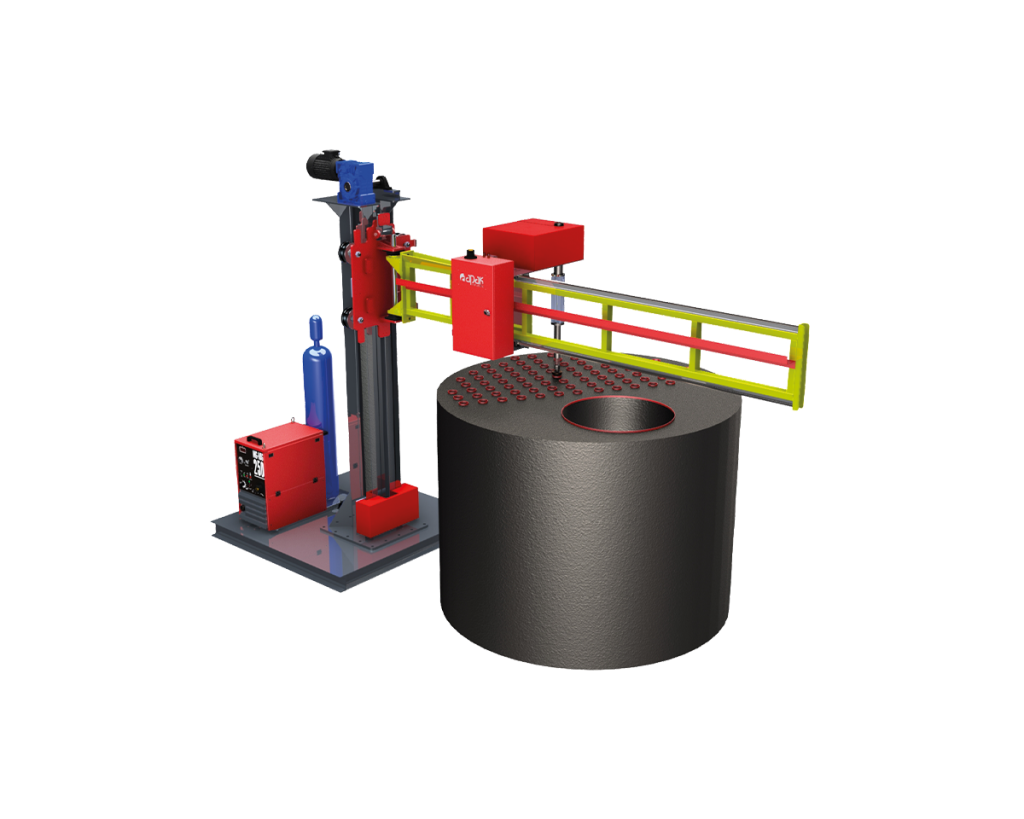

Clamp Forming Machine is a specialized solution developed by Apak Interwelding for the efficient production of clamps and industrial rings. Designed to meet the requirements of various industries, it allows the automatic forming, rolling, and cutting of clamps and hoops in a single process. This not only saves valuable production time but also minimizes manual labor, ensuring higher productivity and lower operational costs.

Thanks to its robust body structure and durable components, the machine delivers long-lasting performance even under heavy-duty industrial conditions. With flexibility in design, it can be adapted to different diameters, thicknesses, and materials, making it suitable for manufacturers in automotive, construction, chemical, and energy sectors.

One of the key advantages of the Clamp Forming Machine is its high level of automation. Operators benefit from simplified workflows, reduced errors, and consistently precise results. By integrating servo drive systems and precision control, the machine guarantees accuracy in every production cycle.

Another benefit is the ability to customize the machine for specific customer needs. Whether producing pipe clamps, chimney clamps, or barrel hoops, Apak Interwelding ensures that each machine can be tailored to individual production requirements.

Choosing the Clamp Forming Machine means investing in efficiency, precision, and reliability. With Apak Interwelding’s expertise and after-sales support, manufacturers gain not only a high-quality machine but also a long-term partner in industrial automation and welding solutions.

- Drain pipe clamps

- Cast pipe clamps

- Barrel lid clamps

- Flue clamps

FEATURES & BENEFITS

Application Examples

Engineered for productivity.

- The diameter and length are adjustable.

- Easy-to-use touchscreen LCD

- Automatic stop by determining the production quantity

- Driveshafts hardened by heat treatment

- Special alloy forming rollers and cutting dies

- Hydraulic cutting system

- Repeatable precision

- Cooling system for extreme heat

- Precision ground spindle and forming rollers

Standard Features

- Touch LDC display

- Hydraulic cutting system

- Hydraulic oil cooling system

- Hardened form rollers

Optional Features

- Marking system

- Coil sheet decoiler

DOCUMENTS

Clamp Forming Machines

English Brochure

Automatisches Orbitalschweißen

Deutsche Broschüre

MEDIA

Our team of experts will help you in all situations

You tell about your production problems, we will offer solutions.

01

Tell us about your problems and your goals in manufacturing.

02

We will contact you and provide detailed negotiations.

03

Let us offer you our specially prepared solution suggestions.