DESCRIPTION

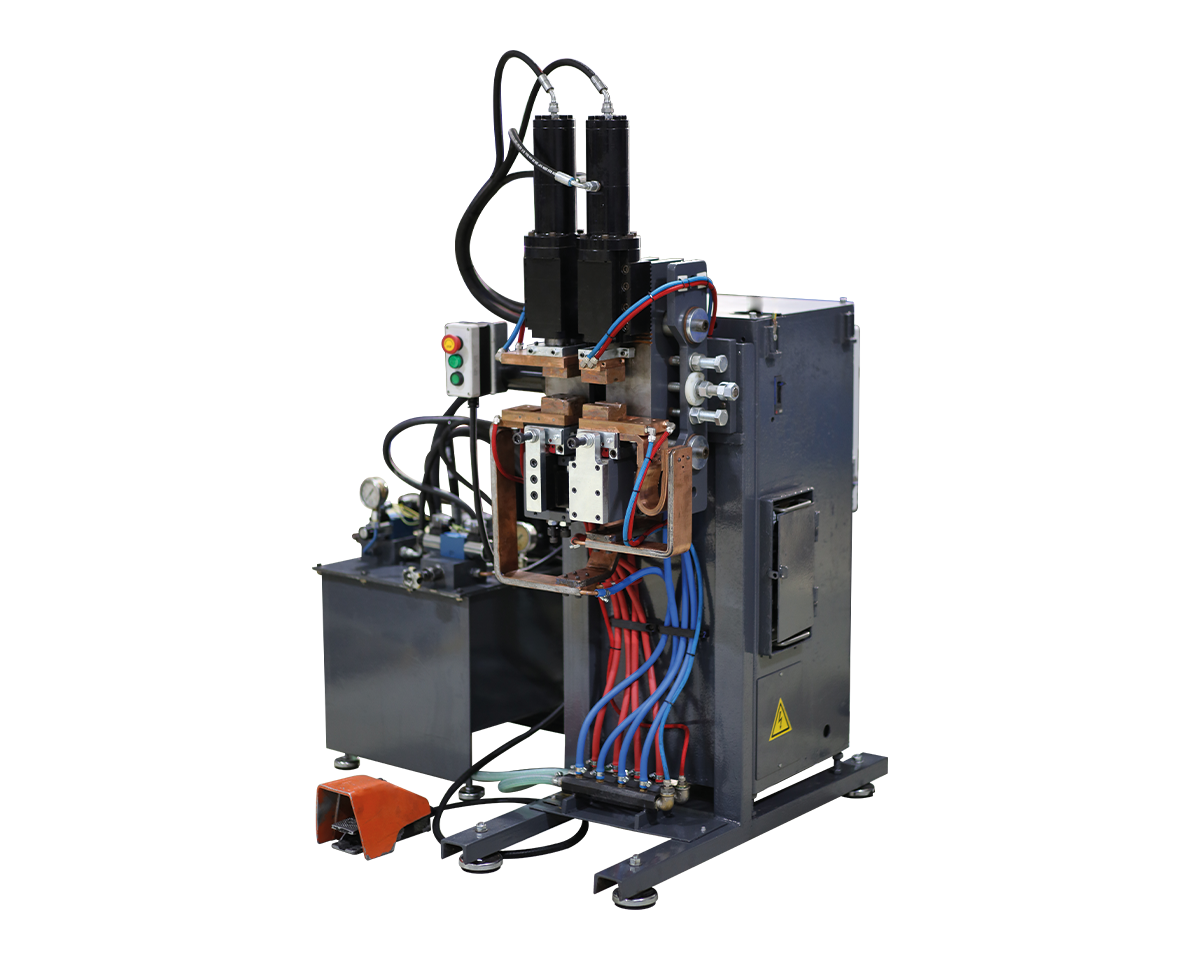

Resistance Butt Welding Machine by Apak Interwelding provides a robust solution for component joining in industrial production. Therefore, it is designed for welding nuts, bolts, circlips, bushings, and fittings directly onto shafts or pipes via resistance butt welding. One welding jaw is fixed, while the other moves horizontally on linear bearings, ensuring precise alignment and minimal deviation.

Moreover, the system allows the clamping and pressing mechanism to be configured as either pneumatic or hydraulic, depending on your application requirements. As a result, you gain flexibility for different production environments. In addition, the welding jaws can be adjusted in three axes, so you can accommodate varying dimensions and part geometries.

Furthermore, the PLC control unit continuously monitors current and adjusts the joining process to maintain optimal welded quality. This ensures consistent, repeatable results over long production runs. Consequently, human error is reduced, and scrap rates decline. Another key advantage is the optional water-cooling system, which prevents overheating during high-current, long weld cycles.

Additionally, this machine supports continuous welding by alternating between two fixtures, enabling high throughput without manual repositioning. Thus, manufacturers can increase output while reducing labor. For example, it is useful in automotive, aerospace, general metal fabrication, and parts manufacturing, where precise, durable joins are required.

In conclusion, the Resistance Butt Welding Machine is a sophisticated welding solution that combines precision mechanics, control automation, and flexible configuration. Therefore, choosing this system means investing in reliable, repeatable joining, improved productivity, and lower operating cost.

- Automotive

- Aerospace

- Industrial applications

- Metalware production

- Resistance Welding

FEATURES & BENEFITS

Application Examples

Engineered for productivity.

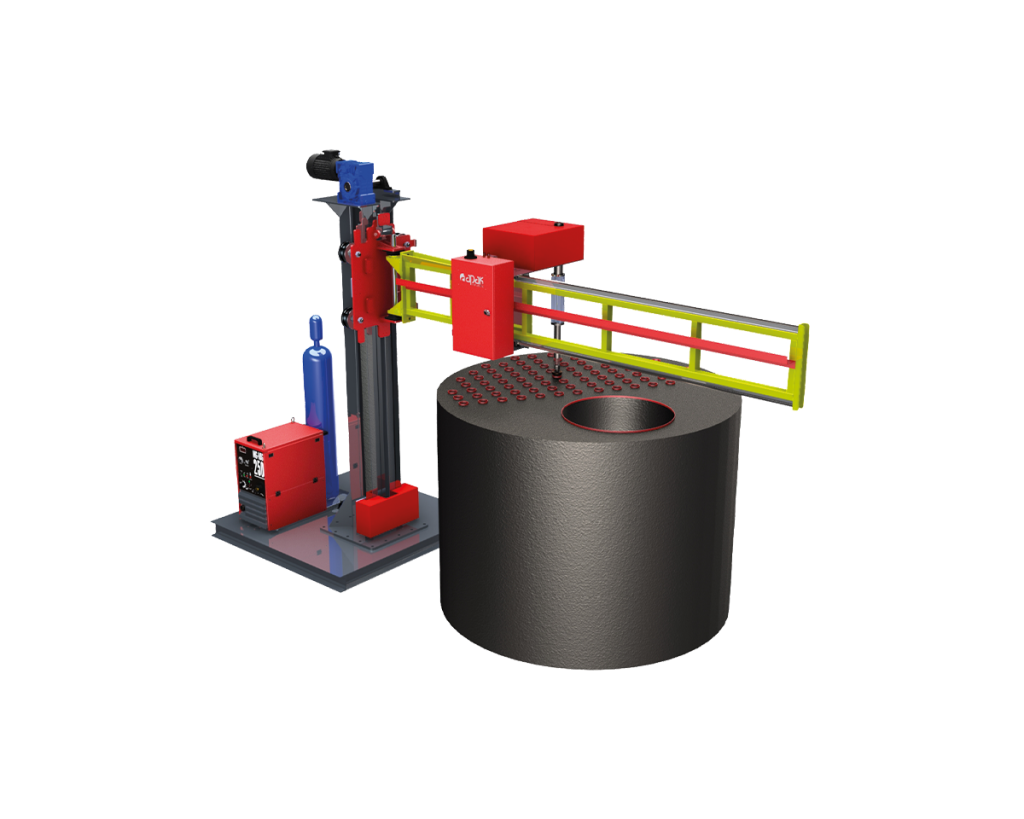

- This system is specifically designed for mass production environments.

- Thanks to its dual fixing jaws, it enables uninterrupted and continuous welding by alternating between the parts to be joined.

- The optional water-cooling unit prevents overheating during high amperage applications and extended welding cycles, ensuring consistent quality and machine durability.

- By minimizing manual labor, the system allows production to continue efficiently and reliably.

- With its resistance welding technology, it provides the flexibility to weld pipes and shafts of various types, diameters, and materials with precision.

Standard Features

- Pulsed welding current

- Starting with the foot pedal

- Pneumatic holding and clamping

Optional Features

- Water cooling unit

- Hydraulic holding and pressing system

- Spot Counter

- Remote control and reporting system

DOCUMENTS

Resistance Butt Welding Machine

English Brochure

Automatisches Orbitalschweißen

Deutsche Broschüre

MEDIA

Our team of experts will help you in all situations

You tell about your production problems, we will offer solutions.

01

Tell us about your problems and your goals in manufacturing.

02

We will contact you and provide detailed negotiations.

03

Let us offer you our specially prepared solution suggestions.