DESCRIPTION

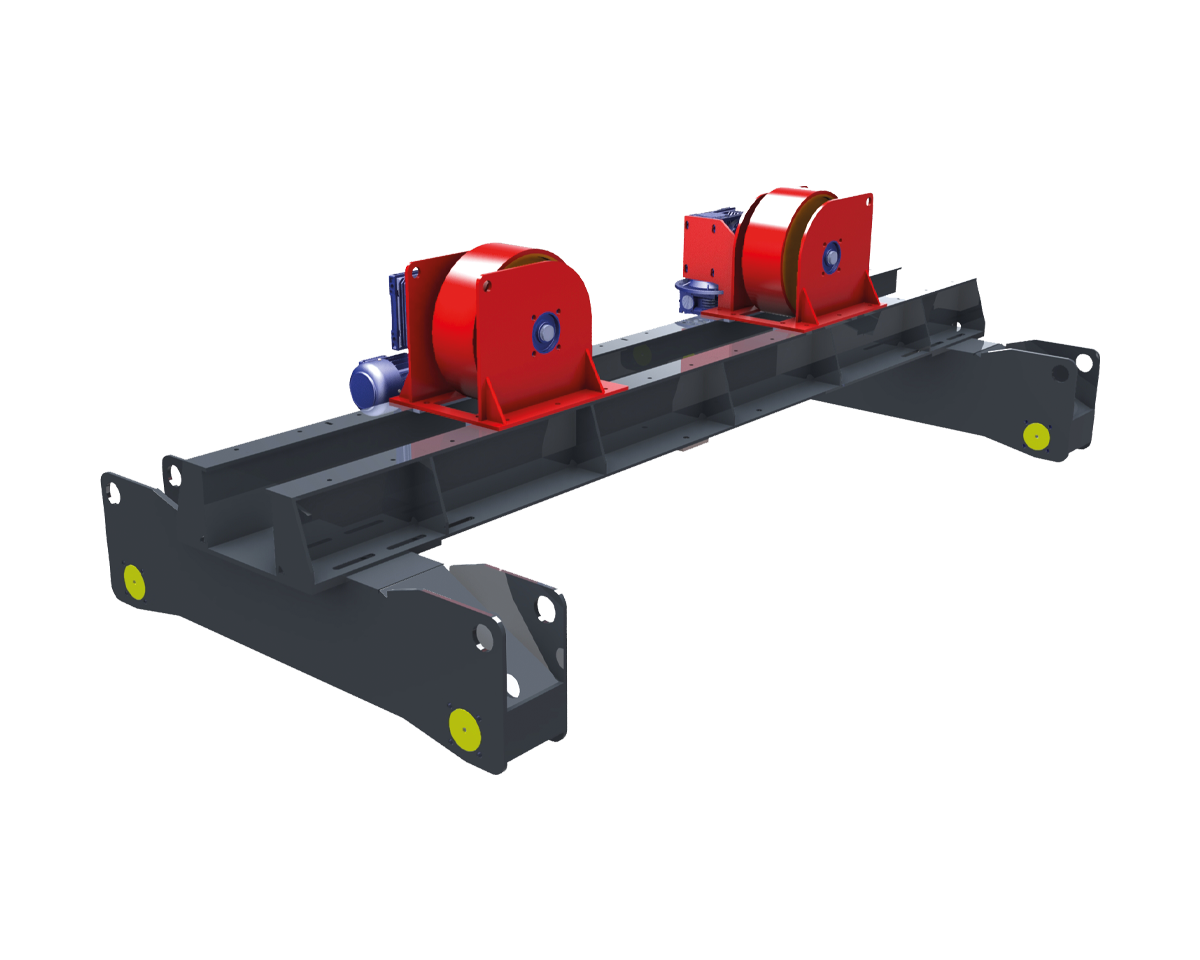

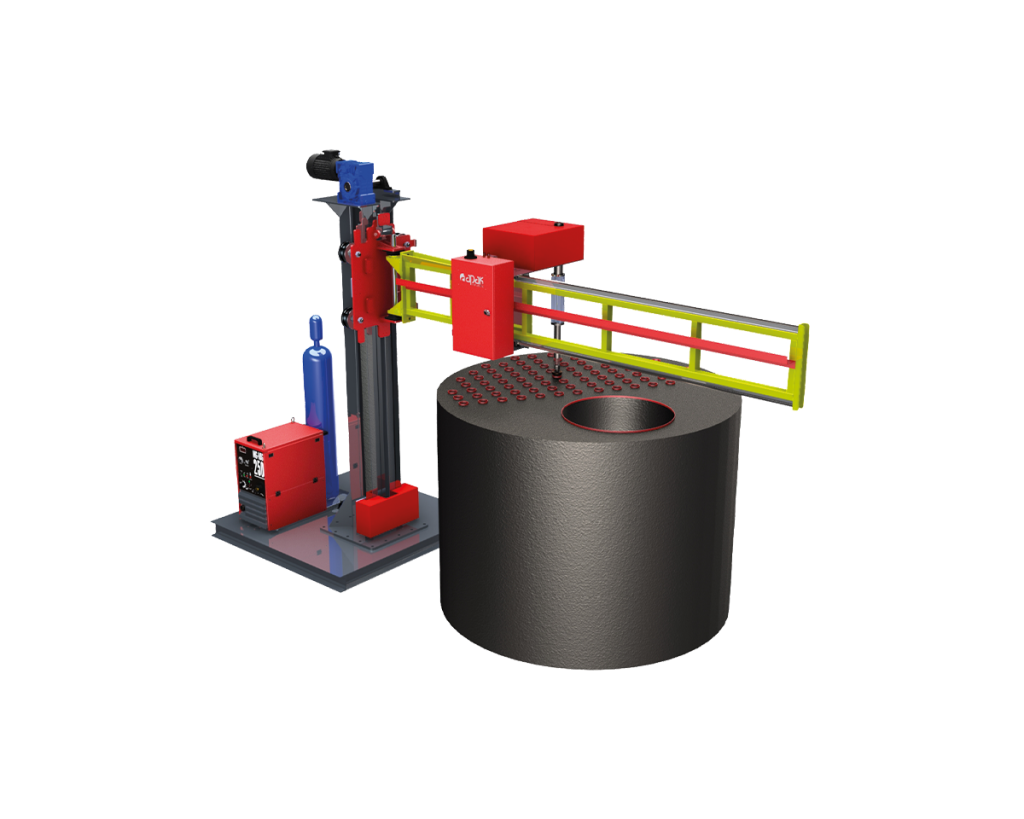

Conventional Rotators from Apak Interwelding are designed to rotate cylindrical workpieces such as pressure vessels, storage tanks, reactor shells, and wind turbine towers to facilitate high-quality welding. Therefore, they serve a vital role in steel fabrication workshops and fuel system manufacturers. Because these rotators reduce reliance on manual repositioning and crane operations, they help save time and labor.

Each rotator set typically comprises one drive unit and one idle unit. Moreover, the number of drive or idle modules can be adjusted to match heavier or longer loads. In addition, the standard product line supports capacities from 1 to 150 tons, but Apak can manufacture special units up to 500 tons for heavy-duty projects.

The cylindrical piece placed on the rollers can rotate clockwise or counterclockwise via the control panel. This flexibility allows precise alignment during welding tasks. Furthermore, features such as digital speed indicators, manual diameter adjustments, motors with brakes, adjustable rotation speeds, and “PU” rollers to absorb vibrations ensure stable and controlled performance.

Optional enhancements include bogie rail travel systems, custom rollers for high-temperature zones, axis support, motorized diameter adjustment, brush earthing systems, rails, and wireless controller systems. Consequently, you can tailor the rotator to your specific production requirements and environment.

Another advantage is that conventional rotators improve both manual and automated welding processes by minimizing crane operations and repositioning. Thus, they increase efficiency in fabrication shops. Moreover, their robust structure ensures durability even under tough industrial conditions.

In conclusion, Apak Interwelding’s Conventional Rotators deliver a balance of economy, reliability, and capacity flexibility. Therefore, whether working on standard cylindrical plates or heavy-duty vessels, investing in these rotators supports consistent weld quality, enhanced productivity, and streamlined operations.

- Pressure vessel manufacturing

- Boiler and tank production

- Pipeline welding

- Steel structure fabrication

- Energy and petrochemical industry

FEATURES & BENEFITS

Standard Features

- Pendant controller with 5 m cable for easy operation

- Polyurethane rollers as standard (steel optional)

- Suitable for TIG, MIG, Plasma, Laser, SAW

- Digital speed indicator on pendant

- Variable speed control & direction switch

- Forward / reverse rotation foot pedal

- Robust steel frame construction

Optional Features

- 7″ touch-screen control panel

- Wireless remote controller

- Servo motor with backlash-free reducer

- Synchronous operation with column & boom

- Manual / motorised roller adjustment

- Anti-drift axial control system

- Motorised bogie for rail travel

- Additional idler sets for long workpieces

DOCUMENTS

Conventional Welding Rotator

English Brochure

Automatisches Orbitalschweißen

Deutsche Broschüre

MEDIA

Our team of experts will help you in all situations

You tell about your production problems, we will offer solutions.

01

Tell us about your problems and your goals in manufacturing.

02

We will contact you and provide detailed negotiations.

03

Let us offer you our specially prepared solution suggestions.