DESCRIPTION

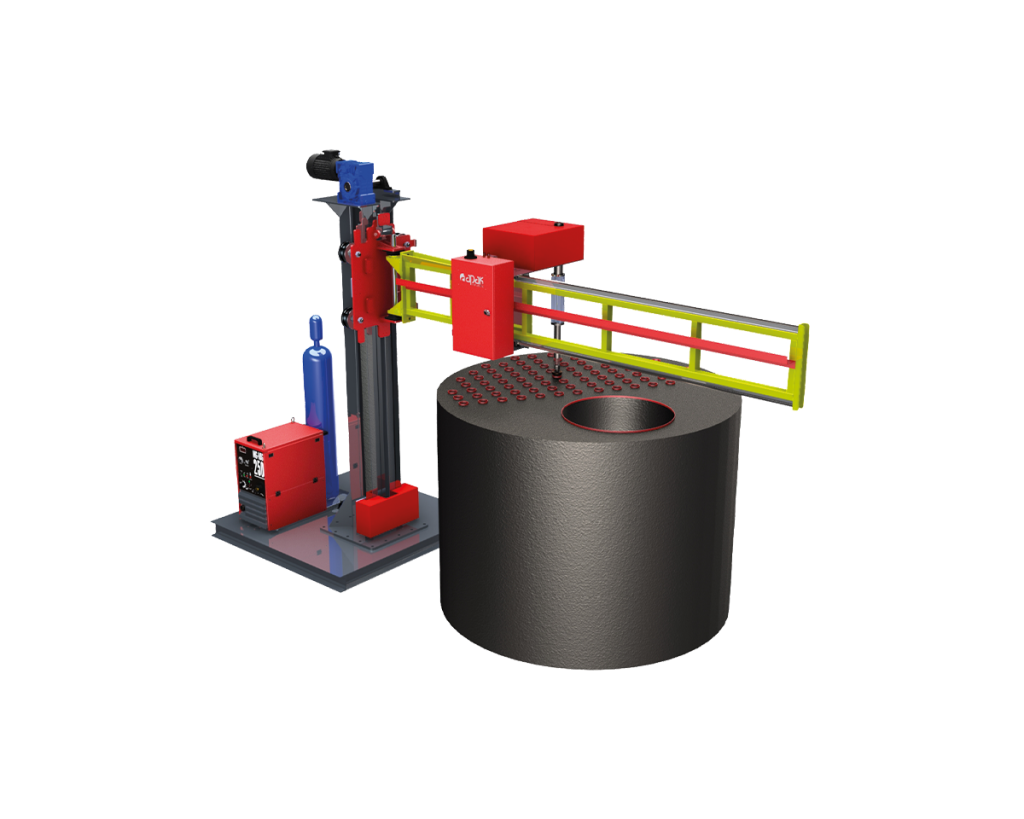

Column and Booms System from Apak Interwelding is engineered to meet demanding industrial welding tasks. Therefore, it is widely used in applications involving cylindrical plates and steel construction, with the ability to weld longitudinally and in circular paths using a rotator or positioner. The design allows the system to be mounted as fixed or mobile based on the production environment.

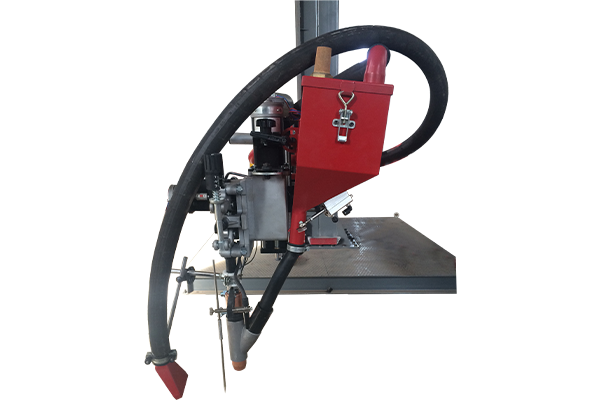

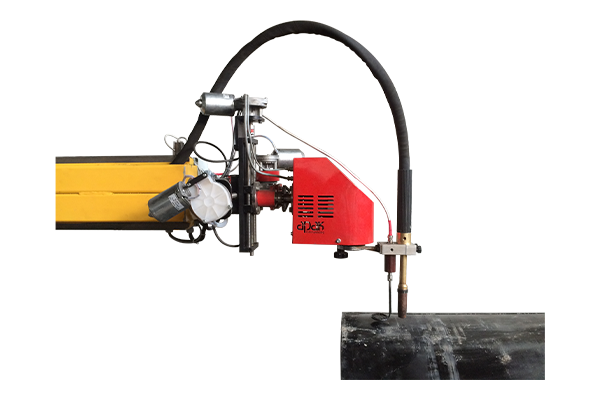

Moreover, the system is compatible with multiple welding methods: GMAW (MIG/MAG), GTAW (TIG), or SAW (Submerged Arc Welding). This flexibility ensures that different materials and thicknesses can be accommodated under one solution. As a result, you don’t need separate machines for different methods.

In addition, Column and Booms systems are available in standard sizes such as 3×3, 4×4, 5×5, and 6×6. They can also be equipped with telescopic boom features when needed, offering extended reach and adaptability. Furthermore, the system includes hardened gear mechanisms and linear rails to deliver vibration-free operation, enhancing weld precision and quality.

The robust structure ensures that long weld runs remain stable and reliable. Thus, the system helps reduce operator fatigue, lowers rework rates, and supports continuous production. Safety features like mechanical locks and counterweights for the boom increase operator confidence and security. Additionally, optional features such as wireless control, motorized rotary columns, tandem welding support, and camera systems enhance usability and automation.

When you need a tailored solution, Apak Interwelding can redesign the column-boom system to suit specific geometries, plate sizes, or production demands. Consequently, you get a welding solution that fits your workflow exactly, rather than forcing a standard machine into your process.

In conclusion, the Column and Booms System is a versatile, reliable, and high-quality welding platform that adapts to diverse industrial needs. Therefore, investing in it means stronger welds, less operator stress, higher throughput, and more consistent outcomes.

- Heat Exchangers

- Pressure Vessels

- LPG & LNG Storage Vessels

- General Fabrication

- Construction

- High Pressure Piping

- High Temperature

- Maintenance & Repair

- Marine Fabrication & Repair

- GMAW (MIG/MAG)

- GTAW (TIG)

- PAW – Plasma Arc Welding

- Submerged Welding Machines (SAW)

FEATURES & BENEFITS

Engineered for productivity.

- Axis movements on linear rail and carriage

- Provides consistent, high-quality sources thanks to variable-frequency drivers.

- Counterweight system for boom

- Safety locks and switches

- Mechanical safety lock against boom drop

Standard Features

- Manual 2-axis adjustment slide for precise height

- Mobile wired control panel

- Linear rails and sliders for backlash-free running

- Safety switches

- Dual speed boom speed selector

- Mechanical safety lock against boom drop

- Boom counterweight system

- Brake motors

- Energy chains for cable protection

- Column fixed to the ground

Optional Features

- Wireless control system

- Motorized rotary column

- Operator seat

- Camera monitoring system

- Tandem welding system

- Enlightenment

- Stairs

- Plc Controlled Converter

- Welding oscillator system – Only with

- GMAW (MIG/MAG) welding

- Walkway (Rail system)

- Powder drying system

- Automatic feeding powder system

DOCUMENTS

Column and Booms

English Brochure

Automatisches Orbitalschweißen

Deutsche Broschüre

MEDIA

Our team of experts will help you in all situations

You tell about your production problems, we will offer solutions.

01

Tell us about your problems and your goals in manufacturing.

02

We will contact you and provide detailed negotiations.

03

Let us offer you our specially prepared solution suggestions.