DESCRIPTION

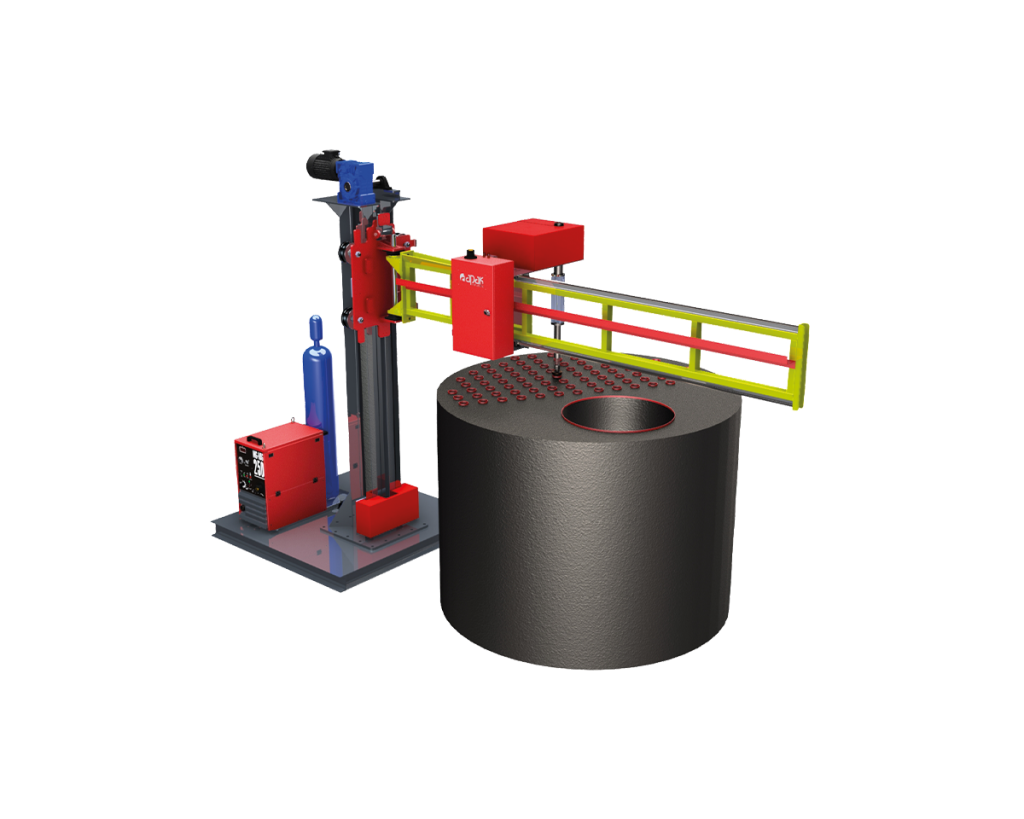

Coil Joining Welding Machine from Apak Interwelding is a high-performance solution designed to meet the increasing demand for reliable coil joining systems in modern production facilities. Therefore, it plays a vital role in industries such as steel, sheet metal, and coil processing. With its robust design, the machine can handle various coil widths and thicknesses, ensuring adaptability across different applications.

Moreover, the system is engineered with operator efficiency in mind. Its ergonomic structure simplifies the welding process, reduces manual workload, and minimizes production downtime. As a result, manufacturers benefit from stable performance and repeatable welding quality. This makes the machine an ideal choice for facilities that require continuous and precise coil joining.

In addition, the Coil Joining Welding Machine is built for durability. Its strong body structure guarantees long service life, while its resistance to wear and corrosion ensures reliable operation even under demanding industrial conditions. Furthermore, the gripper and cutter drive systems can be configured as hydraulic or pneumatic, offering flexibility to match specific production requirements.

Another advantage of this equipment is its mobility. Equipped with carrier rollers, the machine can be easily moved along a rail system. Consequently, it can be separated from the coil line when not in use, which increases production flexibility and improves workflow management.

In conclusion, Apak Interwelding delivers more than just a coil joining solution. By integrating advanced automation and precision engineering, the Coil Joining Welding Machine enables manufacturers to achieve consistent weld quality, faster operation, and lower production costs. Therefore, investing in this system means choosing a durable and future-proof machine that enhances productivity, safety, and efficiency at every stage of the production process.

- Roll forming lines

- Coating lines

- Pipe manufacturing lines

- Continuous annealing lines

- Press and batting lines

- Galvanizing lines

- MIG / MAG

- TIG

- Plasma Welds

FEATURES & BENEFITS

Application Examples

Engineered for productivity.

Advantages of our coil joining welding machines.

- No additional material is required in the welding process

- Machine body and equipment resistant to harsh working environments

- Perfectly aligned weld with precise and wear-free guides

- Variable manual, pneumatic, and hydraulic clamping systems according to the device model to prevent the part from slipping during welding with high-pressure distribution

- The control panel is in a separate cabinet to protect against dirt, dust, and damage.

- Mechanically or pneumatically tensioned spring system for standard welding results

- Hydraulic and pneumatic cutting system depending on cutting capacity

- Double cutter and holder

- Simple and ergonomic design

DOCUMENTS

Coil Joining Welding Machine

English Brochure

Automatisches Orbitalschweißen

Deutsche Broschüre

MEDIA

Our team of experts will help you in all situations

You tell about your production problems, we will offer solutions.

01

Tell us about your problems and your goals in manufacturing.

02

We will contact you and provide detailed negotiations.

03

Let us offer you our specially prepared solution suggestions.