DESCRIPTION

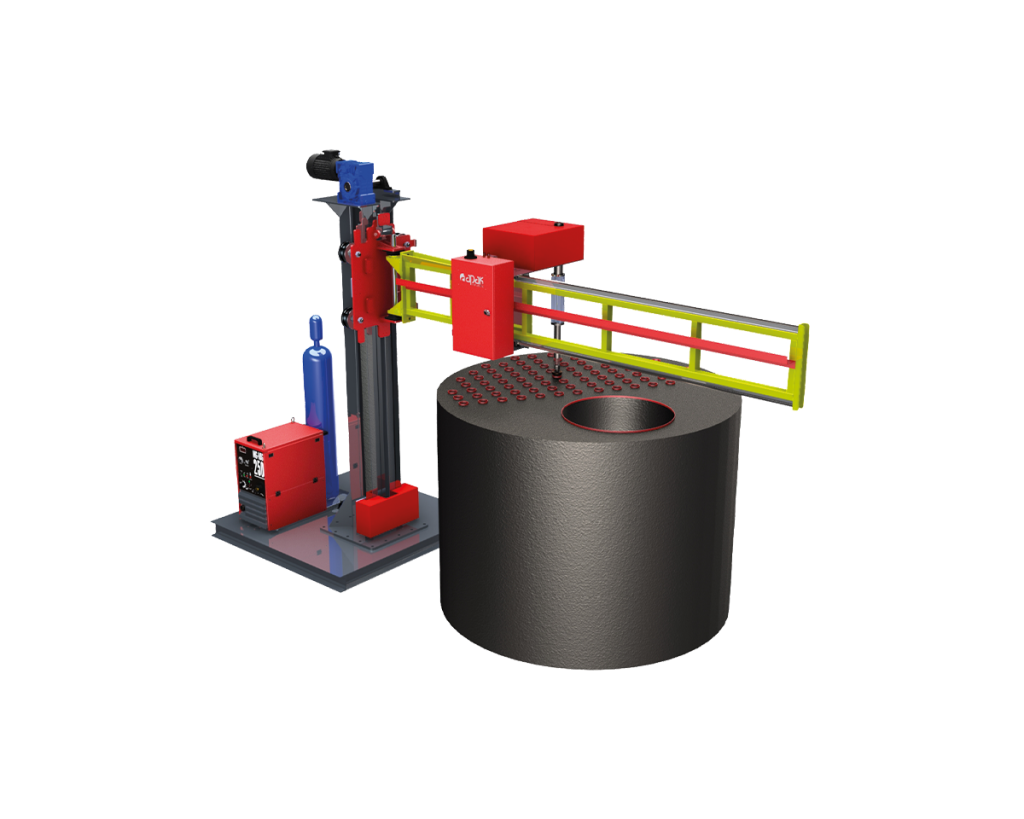

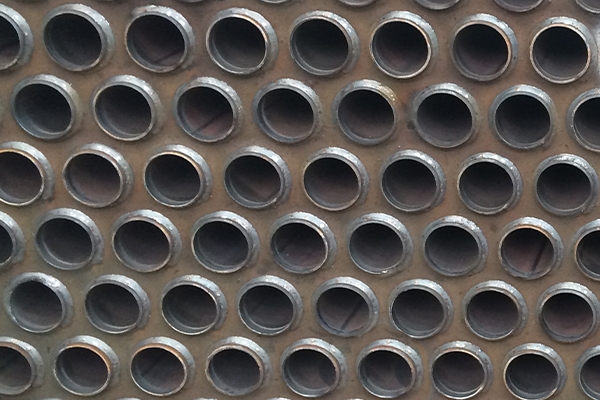

Orbital Welding System by Apak Interwelding is a reliable solution for industries that demand precision. Therefore, it is the preferred choice for boiler manufacturers, heat exchanger producers, and tube-to-tube sheet welding applications. In fact, the system ensures weld quality that meets ASME and EN standards in every cycle.

Moreover, the machine is versatile. It allows the use of unalloyed, low-alloy, high-alloy, and flux-cored MIG wires. As a result, manufacturers can work with different material grades without compromising weld quality. In addition, this flexibility makes the system suitable for a wide range of industrial requirements.

Furthermore, the Orbital Welding System is available in standard 3×3, 4×4, 5×4, and 6×4 capacities. For example, small-scale boiler plants often choose 3×3, while larger facilities rely on 6×4. Consequently, manufacturers can select the configuration that best fits their production volume.

Another advantage is customization. In other words, the system can be redesigned and manufactured according to the specific length and diameter of the customer’s products. Thus, it combines standardized design with tailor-made flexibility.

Additionally, advanced automation ensures repeatable welding results. Servo-driven control and ergonomic design reduce operator workload. As a result, downtime is minimized, safety is improved, and long-term reliability is guaranteed.

In conclusion, choosing the Orbital Welding System means more than acquiring a machine. Indeed, it is an investment in accuracy, durability, and international compliance. Therefore, with Apak Interwelding’s engineering expertise and after-sales support, manufacturers gain a complete solution that strengthens global competitiveness.

- Heating boiler

- Heat exchangers

- Pipe plate welds

- GMAW (MIG/MAG)

FEATURES & BENEFITS

Application Examples

Engineered for productivity.

- Up to 5 times faster welding compared to manual welding

- Axis movements on linear guide and carriage

- Consistent, high-quality welds through variable frequency drives

- Mechanical safety lock against boom drop

- Easy centering system

- No need for qualified personnel

- Easy programming and operation

- Welding diameter from 30 mm to 100 mm

- Compatible with mixed and CO₂ gas

- Usable wire diameter from 0.8 mm to 1.2 mm

Standard Features

- Pneumatic centering

- PLC control system

- Water-cooled welding torch

- 380-degree welding angle

- Burn-Back function

- Lighting system

- 500 Amp GMAW (MIG/MAG) power unit

Optional Features

- Dual-arm welding system

- Synergic welding system

DOCUMENTS

Automatic Orbital Welding System

English Brochure

Automatisches Orbitalschweißen

Deutsche Broschüre

MEDIA

Our team of experts will help you in all situations

You tell about your production problems, we will offer solutions.

01

Tell us about your problems and your goals in manufacturing.

02

We will contact you and provide detailed negotiations.

03

Let us offer you our specially prepared solution suggestions.