DESCRIPTION

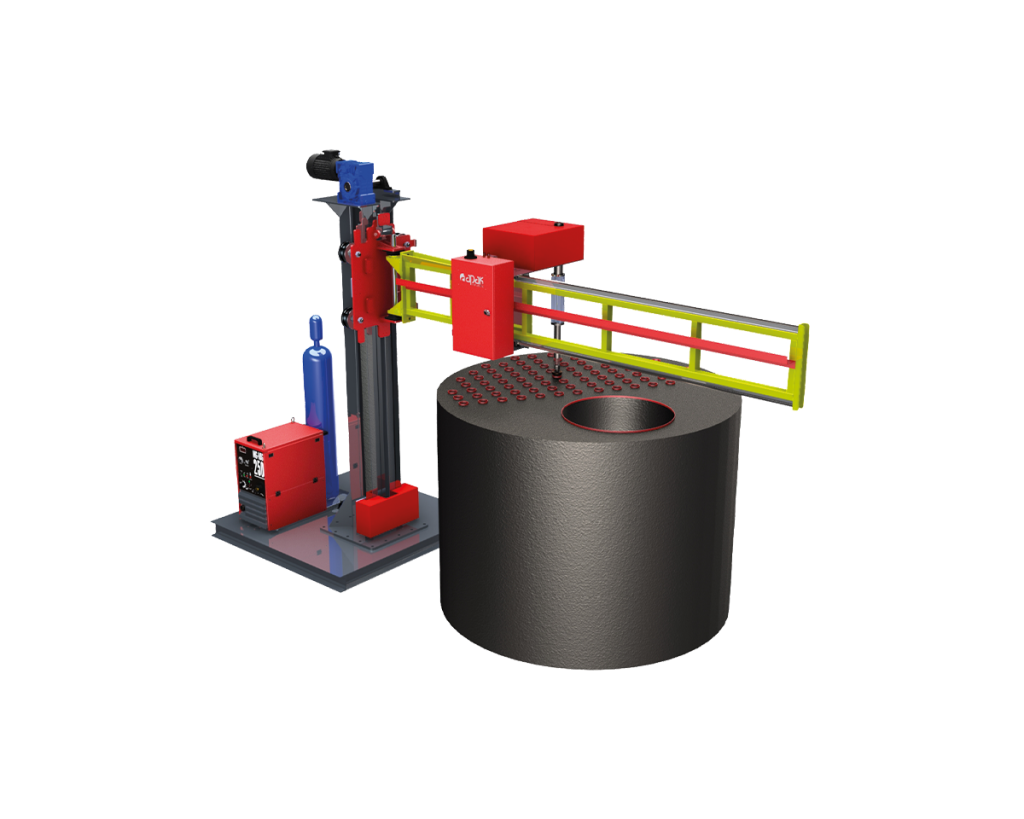

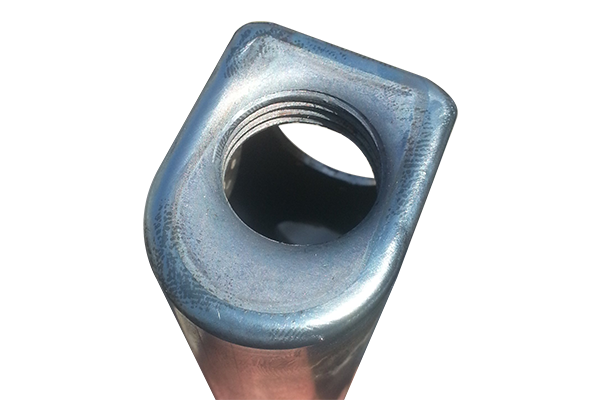

3 Axis CNC Welding Machine is a specialized automation system developed by Apak Interwelding to provide high precision and efficiency in industrial welding applications. Therefore, it is widely used for products such as towel warmers, heating radiators for homes and offices, and decorative items. In fact, it is especially suitable for welding plugs used in butt closing of square, circular, and elliptical pipes and profiles.

Moreover, compared to traditional oxy-acetylene welding, this system prevents overheating of the workpiece. As a result, deformation caused by excessive heat is avoided, and the overall welding quality is significantly improved. In addition, it does not require borax or brass alloy wires, which are commonly used in conventional welding processes. Consequently, production costs are reduced, while output quality remains consistent.

Furthermore, the 3 Axis CNC Welding Machine is designed to minimize reliance on highly skilled welders. Thus, operators can achieve stable results with less effort, and production capacity can be increased without additional labor costs. Another advantage is its adaptability: when standard features are not sufficient, the system can be redesigned and manufactured according to specific business needs.

Additionally, CNC control ensures precise movement on three axes, delivering repeatable results for different part geometries. For example, in the production of towel warmers or decorative radiators, the system guarantees tight and uniform butt welds, ensuring durability and visual quality.

In conclusion, the 3 Axis CNC Welding Machine is more than a standard welding unit. Indeed, it is a flexible automation solution that reduces costs, eliminates deformation risks, and ensures long-term efficiency. Therefore, with Apak Interwelding’s expertise and engineering, manufacturers receive a reliable, adaptable, and future-proof welding system tailored to their industry needs.

- Towel warmer production

- Home and office radiators

- Home decoration products

- Table and chair production

- All sectors where pipes and profiles are used

- GMAW (MIG/MAG)

- GTAW (TIG)

FEATURES & BENEFITS

Application Examples

Engineered for productivity.

- Profile and pipe welding in any form with CAM format

- Easy-to-use interface

- Redesign for workpieces of different sizes needed

- Precise movement on linear rail and carriage

- Repeatable motion precision

- Cab for protection from welding light

- Welding viewing glasses

Standard Features

- Three-axis CNC welding ability

- 2 pieces of 100 x 100 mm working area

- Two blanking slots

- Pneumatic clamping system

- PC and PLC systems used for system control

- Precision linear rails and blocks

- Welding fume and light protection cabinet

- Welding sight glasses

- Water-cooled torch system

- PC system

- Lighting system

Optional Features

- GMAW (MIG/MAG)

- Wire-fed GTAW (TIG) welding system

- Welding fume extraction system

DOCUMENTS

3 Axis CNC Welding Automation

English Brochure

Automatisches Orbitalschweißen

Deutsche Broschüre

MEDIA

Our team of experts will help you in all situations

You tell about your production problems, we will offer solutions.

01

Tell us about your problems and your goals in manufacturing.

02

We will contact you and provide detailed negotiations.

03

Let us offer you our specially prepared solution suggestions.