DESCRIPTION

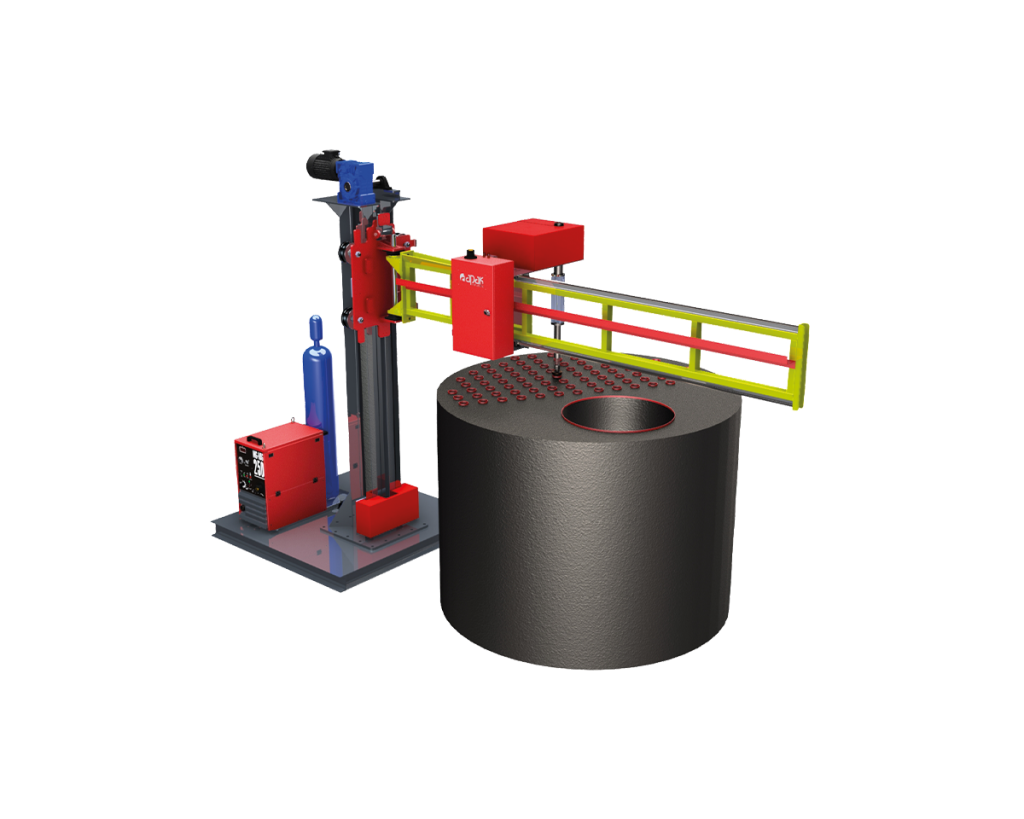

The Column and Boom Welding System represents a key automation solution for manufacturers seeking accuracy, consistency, and flexibility in large-scale welding operations.

It is specifically designed for longitudinal and circumferential welding, ensuring repeatable seam quality across tanks, vessels, and cylindrical components.

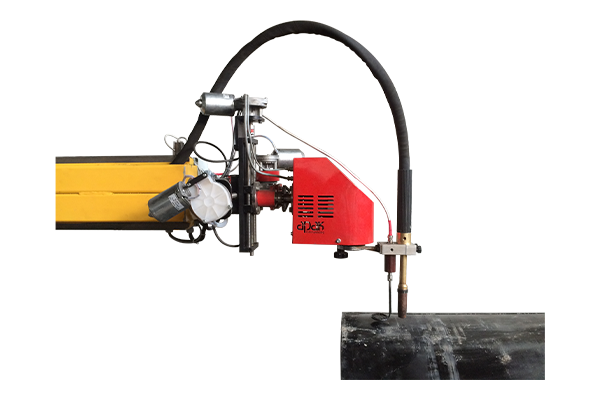

Moreover, this system is adaptable to various welding methods, including GMAW (MIG/MAG), GTAW (TIG), and SAW (Submerged Arc Welding). Thanks to its motorized boom and column design, the torch movement remains stable even in demanding industrial conditions.

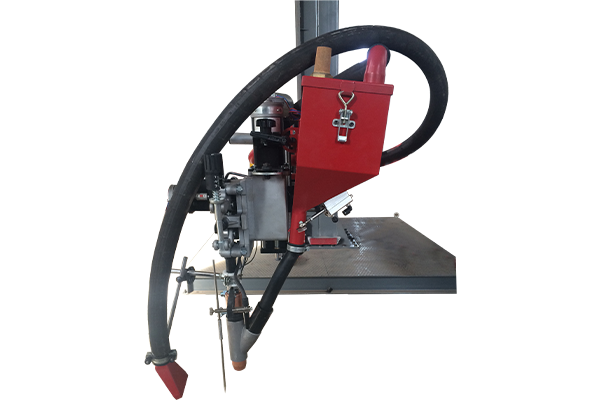

Additionally, operators benefit from advanced automation features such as torch oscillators, seam tracking sensors, and adjustable welding speed controls, all of which contribute to higher efficiency.

By integrating the Column and Boom Welding System with rotators and positioners, manufacturers can achieve fully automated welding lines that minimize downtime and increase productivity.

As a result, this system offers a reliable, safe, and cost-effective welding solution for industries such as boiler manufacturing, energy systems, and pressure vessel fabrication.

- Heat Exchangers

- Pressure Vessels

- LPG & LNG Storage Vessels

- General Fabrication

- Construction

- High Pressure Piping

- High Temperature Applications

- Maintenance & Repair

- Marine Fabrication & Repair

- GMAW (MIG/MAG) – Gas Metal Arc Welding

- GTAW (TIG) – Gas Tungsten Arc Welding

- PAW – Plasma Arc Welding

- SAW – Submerged Arc Welding

FEATURES & BENEFITS

Engineered for productivity.

- Wireless control system

- Motorized rotary column

- Operator seat

- Camera monitoring system

- Tandem welding system

- Lighting system

- Stairs and access platform

- PLC controlled converter

- Welding oscillator system (for GMAW)

- Walkway with rail system

- Powder drying system

- Automatic powder feeding system

Standard Features

- Manual 2-axis adjustment slide for precise height

- Mobile wired control panel

- Linear rails and sliders for backlash-free movement

- Safety switches

- Dual speed selector for boom travel

- Mechanical safety lock against boom drop

- Counterweight system for boom balance

- Brake motors for stability

- Energy chains for cable protection

- Column fixed securely to ground

Optional Features

- Wireless control system

- Motorized rotary column

- Operator seat

- Camera monitoring system

- Tandem welding system

- Lighting system

- Stairs and access platform

- PLC controlled converter

- Welding oscillator system (for GMAW)

- Walkway with rail system

- Powder drying system

- Automatic powder feeding system

DOCUMENTS

Column and Boom Systems

English Brochure

Automatisches Orbitalschweißen

Deutsche Broschüre

MEDIA

Our team of experts will help you in all situations

You tell about your production problems, we will offer solutions.

01

Tell us about your problems and your goals in manufacturing.

02

We will contact you and provide detailed negotiations.

03

Let us offer you our specially prepared solution suggestions.