DESCRIPTION

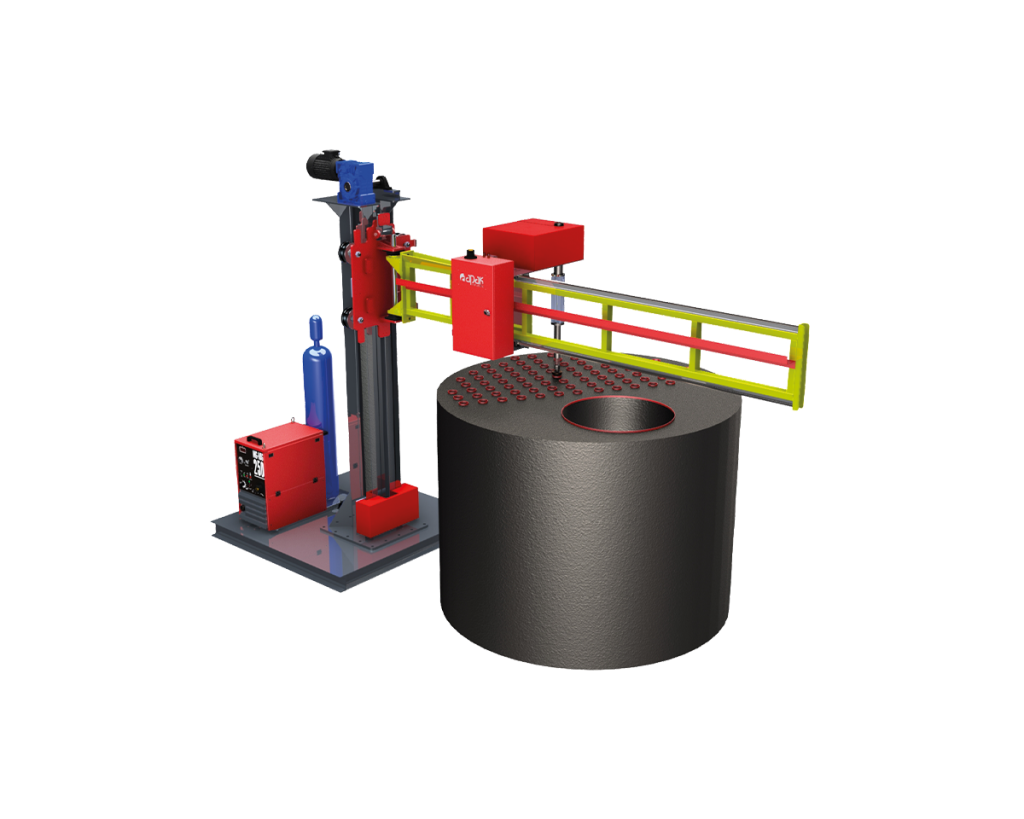

This system developed for the fitting of flexible pipes, that can perform the welding process of flexible pipe, protection sleeve, fitting and ferrule at once.

Mig and Tig welding systems can be used on the system. Thanks to welding oscillation, it can perform large welding casting.

With this system, welding operations of elbows, fittings and joints can be performed.

- It is a system designed to be used in productions with mass production needs. It can perform continuous welding by switching

between the parts to be welded with 2 fixing jaws on the system. It offers a visually flawless starting and ending opportunity with the ability to start welding from different points of the workpiece.

- With this system, you can continue uninterrupted production by minimizing human labor.

- The system, which can be adjusted without being dependent on the shape, has the ability to weld pipes and profiles with each form.

- Both MIG and TIG welding methods can be used on the system.

- Oxy-Fuel Cutting

- Plasma Cutting

- GMAW (MIG/MAG)

- GTAW (TIG)

- PAW – Plasma Arc Welding

- SMAW/MMA (Stick)

- Grinding

FEATURES & BENEFITS

Application Examples

Engineered for productivity.

- It is a system designed to be used in productions with mass production needs. It can perform continuous welding by switching

between the parts to be welded with 2 fixing jaws on the system. - It offers a visually flawless starting and ending opportunity with the ability to start welding from different points of the workpiece.

- With this system, you can continue uninterrupted production by minimizing human labor.

- The system, which can be adjusted without being dependent on the shape, has the ability to weld pipes and profiles with each form.

- Both MIG and TIG welding methods can be used on the system.

Standard Features

- 3 axis CNC welding ability

- 2 pieces of 100 x 100 mm working are

- 2 blanking slots

- Pneumatic clamping system

- PC and PLC system used for system control

- Precision linear rails and blocks

- Welding fume and light protection cabinet

- Welding sight glasses

- Water cooled torch system

- Welding area lighting lamps

- PC system

- Lighting system

Optional Features

- 3 axis CNC welding ability

- 2 pieces of 100 x 100 mm working are

- 2 blanking slots

- Pneumatic clamping system

- PC and PLC system used for system control

- Precision linear rails and blocks

- Welding fume and light protection cabinet

- Welding sight glasses

- Water cooled torch system

- Welding area lighting lamps

- PC system

- Lighting system

DOCUMENTS

Circular Welding Automation

English Brochure

Automatisches Orbitalschweißen

Deutsche Broschüre

MEDIA

Our team of experts will help you in all situations

You tell about your production problems, we will offer solutions.

01

Tell us about your problems and your goals in manufacturing.

02

We will contact you and provide detailed negotiations.

03

Let us offer you our specially prepared solution suggestions.