DESCRIPTION

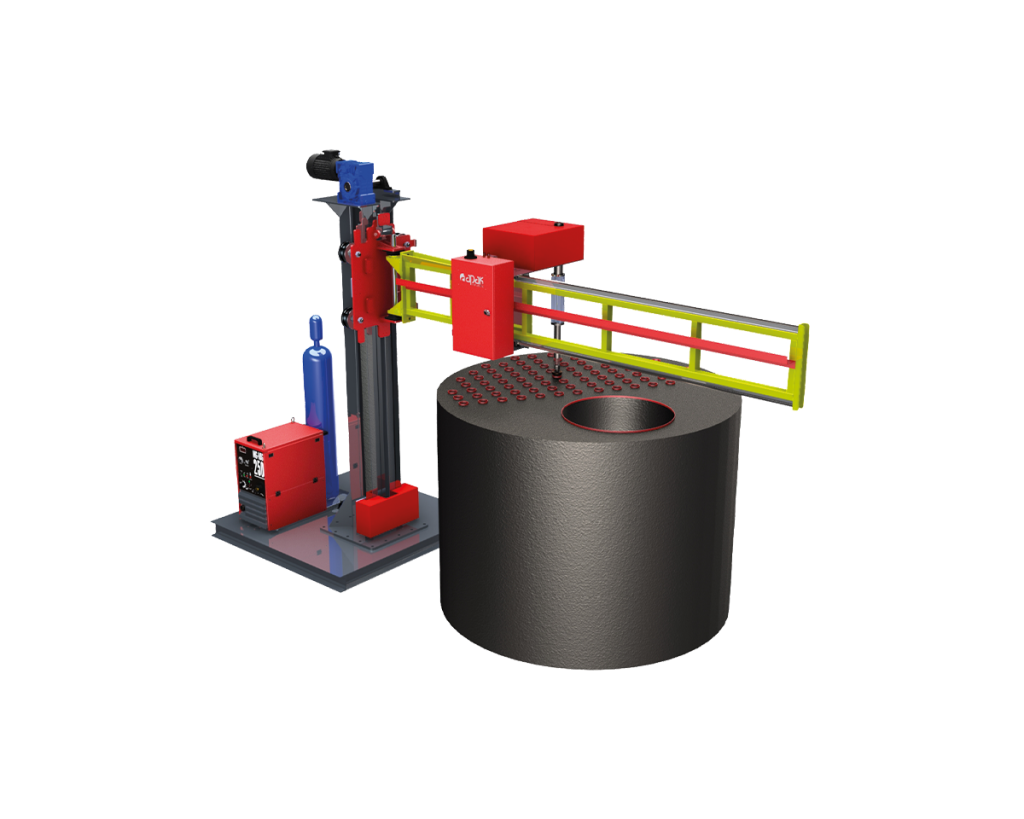

Automation Welding Solutions from Apak Interwelding provide manufacturers with advanced and flexible systems that improve efficiency and reduce production costs. Therefore, they are widely used in industries such as steel construction, automotive, energy, and general metal fabrication. In fact, these solutions are designed to simplify complex welding tasks and guarantee repeatable quality.

Moreover, the systems can be configured for automated or manual material feeding. As a result, manufacturers can select the best option for their production needs. In addition, multi-axis movement and precision part-holding systems ensure stable positioning and accurate welding, even for complex geometries.

Furthermore, different welding technologies such as MIG/MAG, TIG, and plasma can be integrated. Consequently, the systems adapt to diverse applications and guarantee consistent weld quality across a wide range of materials and thicknesses. Another advantage is the ergonomic and user-friendly design, which reduces operator workload and improves safety during long welding cycles.

Additionally, the Automation Welding Solutions are built with robust and durable structures, ensuring long service life in demanding industrial environments. Thus, downtime is minimized, and productivity is maximized. For example, in automotive production, automated feeding combined with CNC-controlled welding achieves faster cycle times without compromising quality.

In conclusion, the Automation Welding Solutions by Apak Interwelding are more than standard automation systems. Indeed, they are tailored solutions that integrate advanced technology, flexible designs, and precision engineering. Therefore, choosing these systems means investing in productivity, cost reduction, and reliable performance that strengthen competitiveness in global markets.

- General Fabrication

- Robotics

- Robotics/ Hard Automation

- Automotive

- Automotive supply industry

- Metal goods production

- Household appliances

- Office and home supplies

- Metal toy production

- Motorcycles and bicycles

- Machine parts

- All metal alloy productions

- Plasma Cutting

- GMAW (MIG/MAG)

- GTAW (TIG)

- PAW – Plasma Arc Welding

- Submerged Welding Machines (SAW)

FEATURES & BENEFITS

Application Examples

Engineered for productivity.

- It is a system designed to be used in productions with mass production needs. It can perform continuous welding by switching

between the parts to be welded with 2 fixing jaws on the system. - It offers a visually flawless starting and ending opportunity with the ability to start welding from different points of the workpiece.

- With this system, you can continue uninterrupted production by minimizing human labor.

- The system, which can be adjusted without being dependent on the shape, has the ability to weld pipes and profiles with each form.

- Both MIG and TIG welding methods can be used on the system.

Contact us immediately for the automation welding solutions you need, and add speed and quality to your production with our system solutions.

DOCUMENTS

Automation welding solutions

English Brochure

Automatisches Orbitalschweißen

Deutsche Broschüre

MEDIA

Our team of experts will help you in all situations

You tell about your production problems, we will offer solutions.

01

Tell us about your problems and your goals in manufacturing.

02

We will contact you and provide detailed negotiations.

03

Let us offer you our specially prepared solution suggestions.