DESCRIPTION

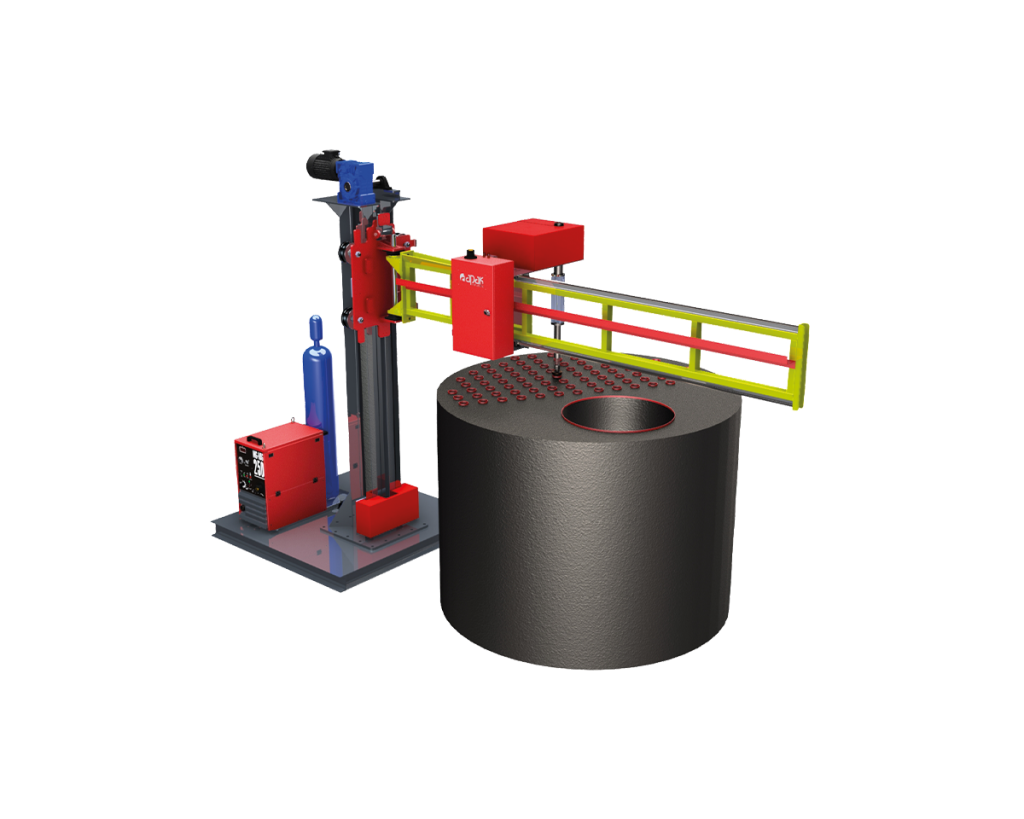

Automatic Drilling and Pin Driving System; is designed to drill holes and drive pins on aluminum, plastic, and iron pipes.

With this system, which has a pin feeding system, it is possible to drill holes at desired intervals in productions where two lines or similar parts must be combined, such as aluminum radiator manufacturers, and perform pin driving simultaneously.

It can complete the workpiece operations without needing personnel, rearranging the feeding unit for different pin forms.

It is an example of our systems that can be designed from seven for the required sector and the product produced.

- Aluminum radiator production

- Water distribution manifolds

- All sectors that require drilling and pin driving on pipes

FEATURES & BENEFITS

Application Examples

Engineered for productivity.

- Redesign according to production

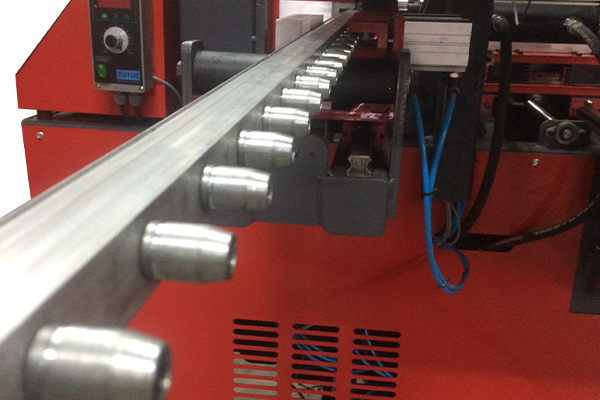

- Interchangeable profile slide

- Anti-scratch surface coating

- High-speed Spindle motor for aluminum alloy materials

- Jam warning system

- Automatic pin feeding system

- Hydraulic oil cooling radiator

- Hole drilling with repeatable precision

Standard Features

- PLC control system

- Easy operation with touchscreen LCD display

- Drill bit cooling

- Pneumatic clamping jaws

- Hydraulic pin mounting

- Precise movement on linear rail and trolley

- Spindle motors

Optional Features

- Dust extraction system

- Machine Cabin

- Vibratory pin feeding system

DOCUMENTS

Automatic Drilling and Pin Driving System

English Brochure

Automatisches Orbitalschweißen

Deutsche Broschüre

MEDIA

Our team of experts will help you in all situations

You tell about your production problems, we will offer solutions.

01

Tell us about your problems and your goals in manufacturing.

02

We will contact you and provide detailed negotiations.

03

Let us offer you our specially prepared solution suggestions.