DESCRIPTION

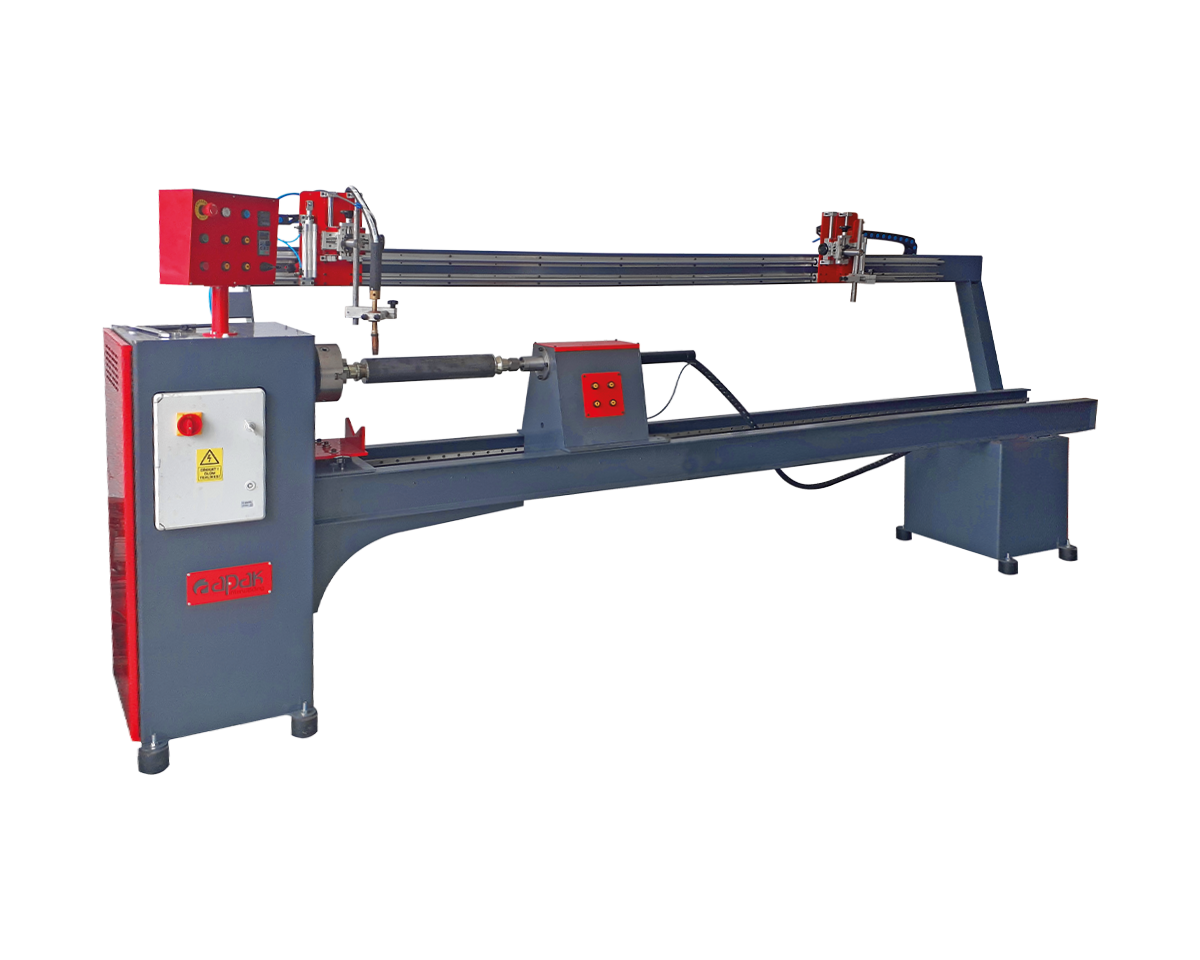

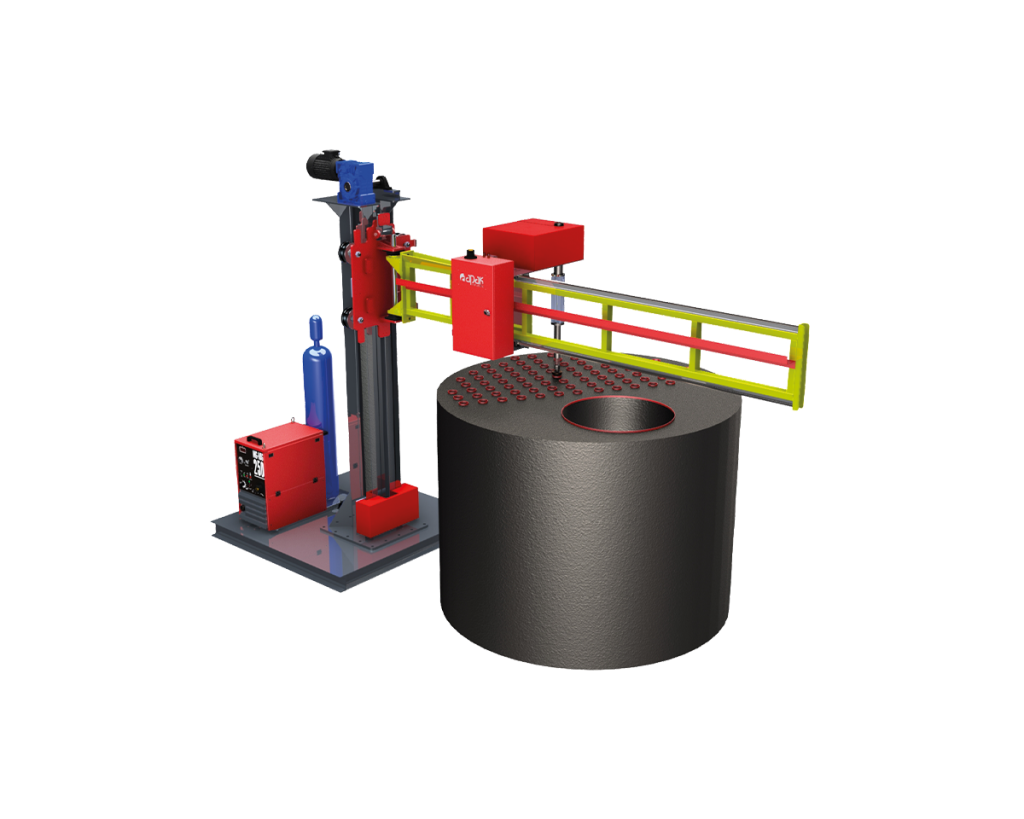

The Cylindrical Welding Automation system from Apak Interwelding provides a complete circular welding system for cylindrical shells, pipes, and tanks. Designed as an advanced orbital welding automation, it offers consistent precision and productivity for both circumferential and longitudinal welds. The system integrates servo-controlled rotation, hydraulic clamping, and programmable parameters to achieve perfect seam alignment and repeatability.

Supporting MIG/MAG, TIG, and SAW processes, this pipe welding system adapts to all material thicknesses and diameters. Optional modules like dual-torch operation, fume extraction, and PLC control expand flexibility. With its rigid frame and smooth drive mechanics, Cylindrical Welding Automation delivers up to five times faster cycle time compared to manual welding – ideal for pressure vessels, boilers, pipe spools, and circular components requiring durable weld quality.

- Heat Exchangers

- Pressure Vessels

- LPG & LNG Storage Tanks

- General Fabrication

- High Pressure Piping

- Fire extinguishers

- Conveyor Belt Rollers

- Marine Fabrication & Repair

- Pipe Flange Welding

- GMAW (MIG/MAG)

- GTAW (TIG)

- PAW – Plasma Arc Welding

- Submerged Welding Machines (SAW)

FEATURES & BENEFITS

Application Examples

Engineered for productivity.

- The axis movements on the linear guide and carrier provide precise and smooth positioning.

- Variable frequency drives ensure consistent and high-quality welding performance.

- Up to 5 times faster welding compared to manual methods.

- Easy centering system for fast and accurate positioning.

- No need for highly skilled operators.

- Simple programming and user-friendly operation with minimal training.

Standard Features

- Rotary chuck for centering different workpieces

- Carriage slide for precise adjustment of torch height

- Pneumatic pusher for quick torch approach

- Pneumatic back-pressure system for safe clamping

- Adjustable rotation angle for flexibility

- Adjustable rotation speed for process optimization

- Linear torch guides for precise movement

- Integration capability with GMAW (MIG/MAG), GTAW (TIG), PAW (Plasma Arc Welding) and SAW (Submerged Arc Welding) systems

- Illumination system for the welding area

Optional Features

- Special centering components for product-specific requirements

- Dual torch carriage system for simultaneous welding

- Hydraulic centering system for additional clamping pressure

- PLC-controlled interface for circular and longitudinal automatic welding

- Welding oscillator for wide weld seams

- Fume extraction systems for a safer working environment

DOCUMENTS

Cylindrical Welding Automation

English Brochure

Automatisches Orbitalschweißen

Deutsche Broschüre

MEDIA

Our team of experts will help you in all situations

You tell about your production problems, we will offer solutions.

01

Tell us about your problems and your goals in manufacturing.

02

We will contact you and provide detailed negotiations.

03

Let us offer you our specially prepared solution suggestions.