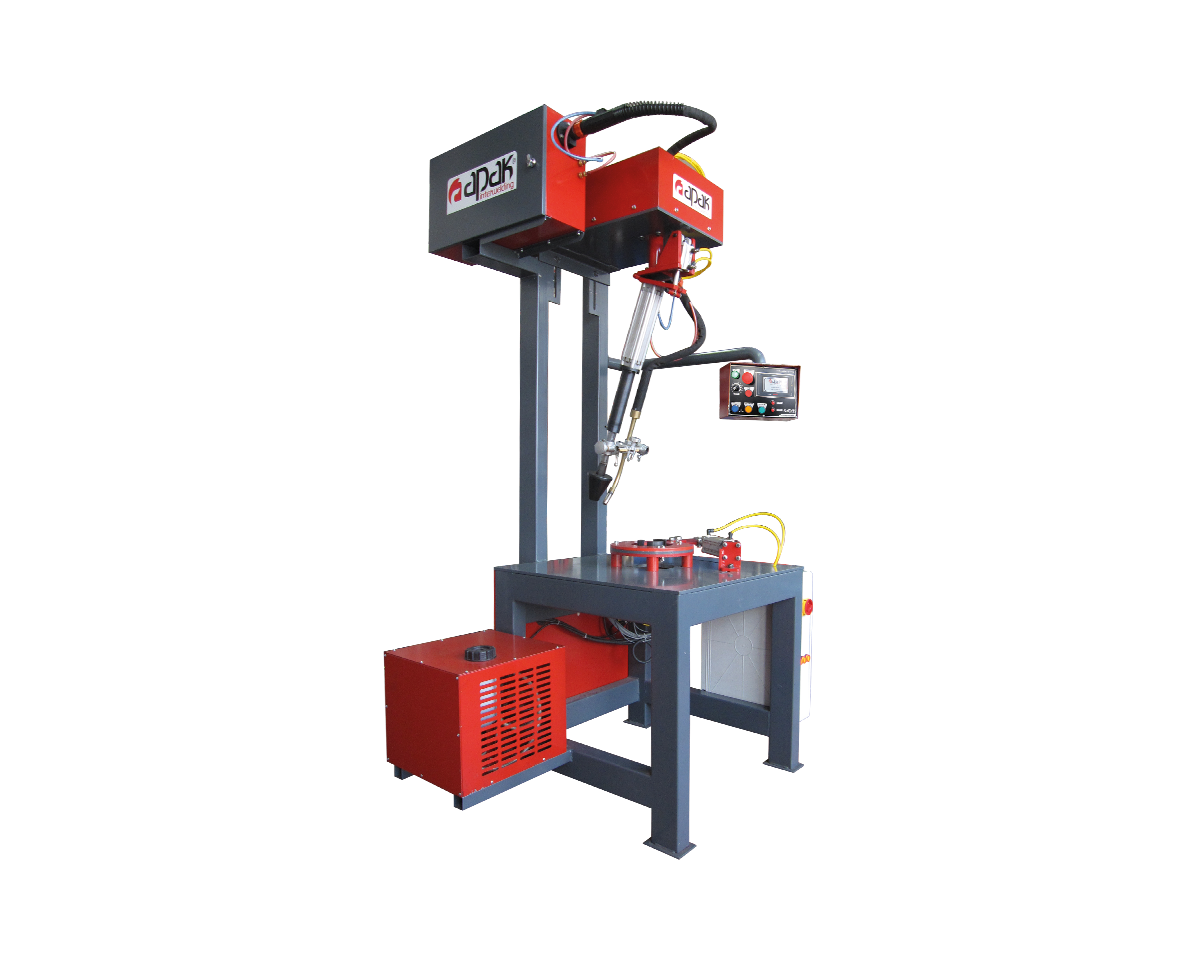

DESCRIPTION

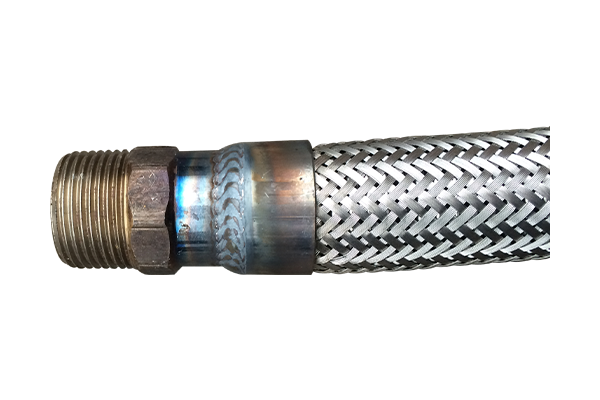

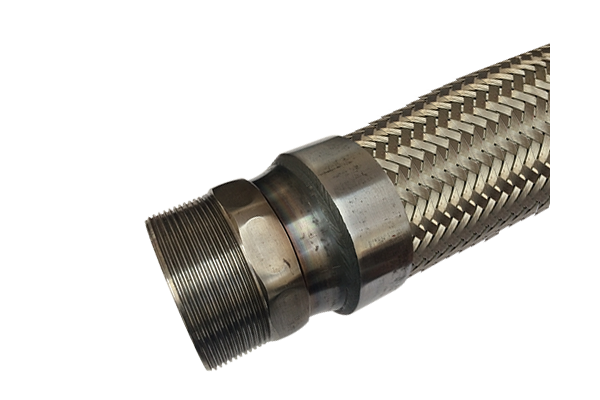

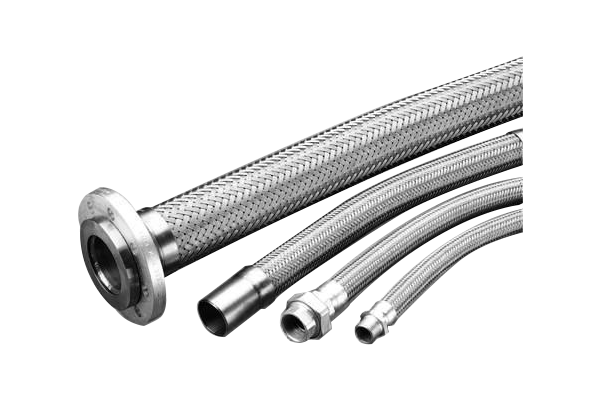

Flexible Pipe Welding Machine; örgülü ve örgüsüz esnek boruların alın kaynak işlemleri için tasarlanmıştır. Esnek hortumların rekor, dirsek ve flanş kaynakları için kusursuz kaynak sonuçları elde edersiniz.

Kolay kullanımı ile kalifiye personel ihtiyacını minimum seviyeye çekebilir üretim hacminizi artırmanıza imkan sağlar.

Geleneksen Oksi asetilen kaynağında oluşan aşırı ısından dolayı hortumda oluşacak deformasyonların önüne geçmek mümkündür.

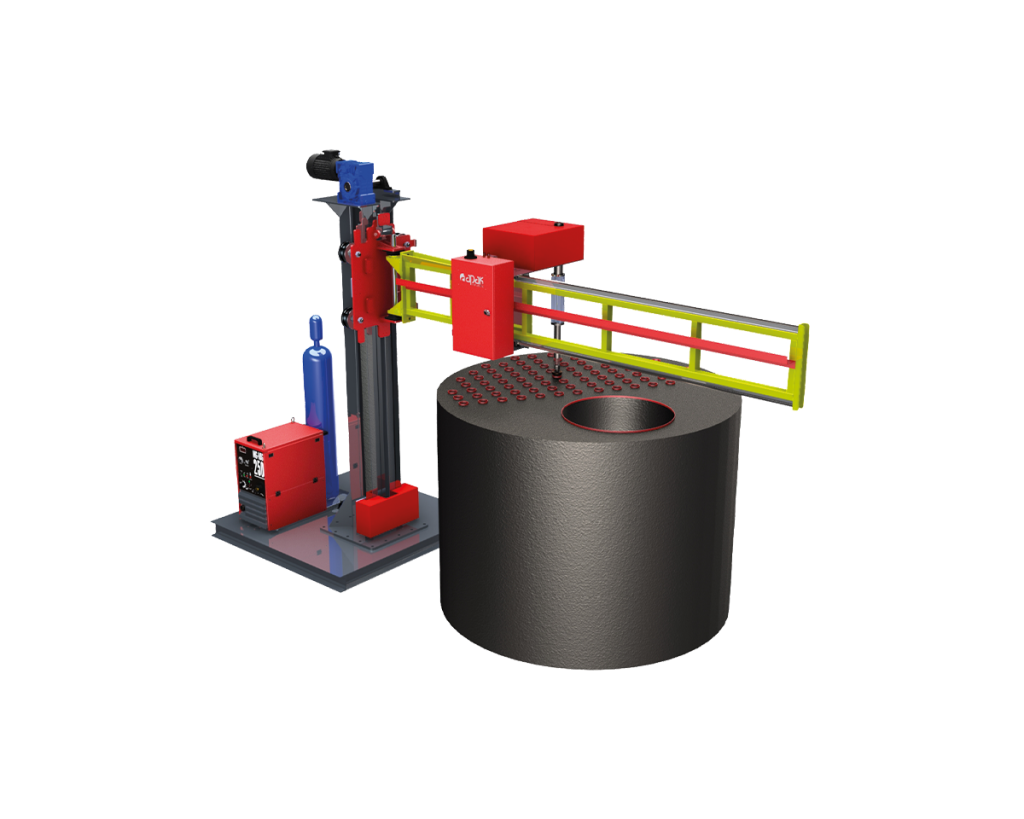

Sistem üzerinde osilatörlü GMAW (MIG/MAG) ve tel beslemeli GTAW (TIG) kaynak yöntemleri kullanılabilir.

Uzun kaynak sürelerinde ki operetör yorgunluklarını önlemenizi sağlar ve sızdırma sorunlarını en aza indirmenize olanak sağlar.

3/4″ – 1″ kapasitesine sahip standart tutma ölçüsünün yanı sıra ürettiğiniz farklı ölçülerde ki esnek hortumların kaynak işlemleri için sistem yeniden tasarlanabilir.

Flexible Pipe Welding Machine; Designed for butt welding of braided and non-braided flexible pipes. You get perfect welding results for union, elbow, and flange welding of flexible hoses.

With its easy use, it can minimize the need for qualified personnel and allows you to increase your production volume.

It is possible to prevent deformations in the hose due to overheating in conventional Oxy-acetylene welding.

Oscillator GMAW (MIG/MAG) and wire-fed GTAW (TIG) welding methods can be used on the system.

It allows you to avoid operator fatigue during long welding times and will enable you to minimize leakage problems.

In addition to the standard holding size of 3/4″ – 1″, the system can be redesigned for welding operations of flexible hoses of different sizes that you produce.

- Steam transport pipes

- Compressed air pipes

- Hot oil pipes

- Heating, ventilation, and air conditioning systems

- Chemical and petrochemical plants

- Shipbuilding and drilling facilities

- Oil and gas processes

- Aircraft industry

- Food and chemical enterprises

- GMAW (MIG/MAG)

- GTAW (TIG)

FEATURES & BENEFITS

Application Examples

Engineered for productivity.

- At least four times faster than manual welding

- Perfect weld seams

- No specialist welder is required.

- Repeatable welding precision

- Easy-to-use interface

Standard Features

- Flexible hose holding capacity in 3/4″ – 1″ size range

- Pneumatic centering

- Refrigerant gas system

- GMAW (MIG/MAG) welding system

- PLC control system

- Touchscreen LCD control panel

Optional Features

- Welding oscillator

- GTAW (TIG) welding system

- Wire feed system for GTAW (TIG) welding

- Lighting

DOCUMENTS

Flexible Pipe Welding Machine

English Brochure

Automatisches Orbitalschweißen

Deutsche Broschüre

MEDIA

Our team of experts will help you in all situations

You tell about your production problems, we will offer solutions.

01

Tell us about your problems and your goals in manufacturing.

02

We will contact you and provide detailed negotiations.

03

Let us offer you our specially prepared solution suggestions.