DESCRIPTION

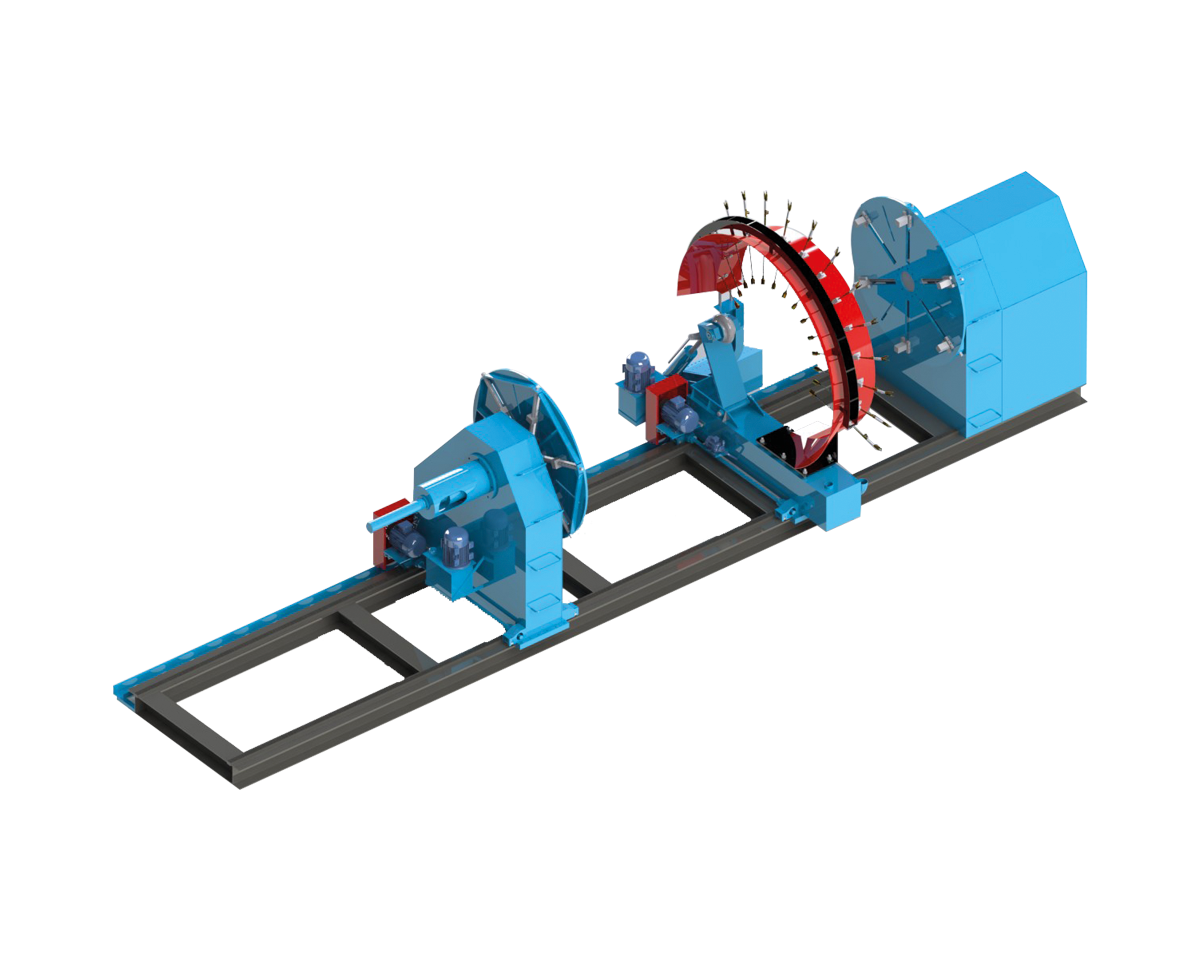

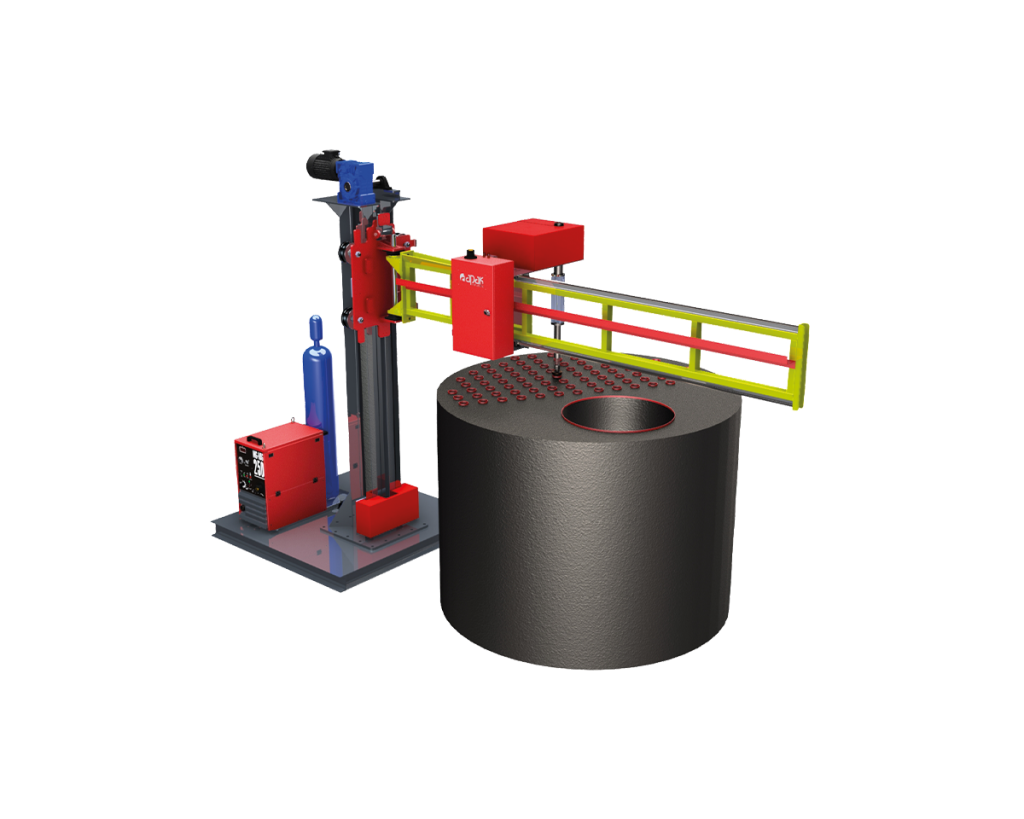

Corrugated Furnace Machine by Apak Interwelding is a high-performance solution. It produces corrugated furnace tubes with precision and reliability. These tubes are key components in boilers, heat exchangers, and energy systems. Therefore, compliance with international standards is essential. Our machine is designed to meet ASME and EN requirements. This ensures safe and efficient operation in every industry.

Moreover, the system uses advanced automation. It can form furnace tubes in different diameters, lengths, and thicknesses. Each process runs with high consistency. As a result, manual errors are eliminated and repeatable quality is guaranteed. The ability to comply with ASME and EN standards gives manufacturers strong confidence. They can meet customer needs and regulatory demands without compromise.

In addition, the machine is built with a robust structure. Durable components allow continuous heavy-duty operation. Hydraulic and servo-driven systems ensure smooth forming and precise corrugation. Automation reduces operator effort and minimizes downtime. It also improves workplace safety.

Another advantage is flexibility. The corrugated tube forming system adapts to different specifications. It still delivers accurate results every time. Consequently, it is the ideal choice for boiler manufacturers, energy plants, and tube producers. They benefit from both quality and compliance.

In conclusion, choosing the Corrugated Furnace Machine means investing in efficiency and durability. It also guarantees compliance with ASME and EN standards. Combined with Apak Interwelding’s engineering expertise and after-sales support, this system offers a future-proof solution for global industries.

- Steam boiler

- All sectors requiring hot-formed pipes

- Propane

- Natural gas

FEATURES & BENEFITS

Application Examples

Engineered for productivity.

- Redesign according to material diameter and length

- Number of burners according to material thickness

- Heavy duty bearings

- Propane or natural gas heating

- Automatic feed between bends

- Bending dimension control

- Easy-to-use control panel

- Counter hydraulic pressure system to prevent cylindrical part dropping

- Hydraulic Bending

- Water cooling system

Contact us immediately for the corrugated furnace machine you need, and add speed and quality to your production with our system solutions.

If it is not the machine you need, but only the steam boiler corrugated oven, we provide service with our existing machines. Do not forget that we can serve you with the material quality and dimensions you want. You can benefit from high quality and attractive prices according to the technical document you send us.

DOCUMENTS

Corrugated Furnace Machine

English Brochure

Automatisches Orbitalschweißen

Deutsche Broschüre

MEDIA

Our team of experts will help you in all situations

You tell about your production problems, we will offer solutions.

01

Tell us about your problems and your goals in manufacturing.

02

We will contact you and provide detailed negotiations.

03

Let us offer you our specially prepared solution suggestions.