DESCRIPTION

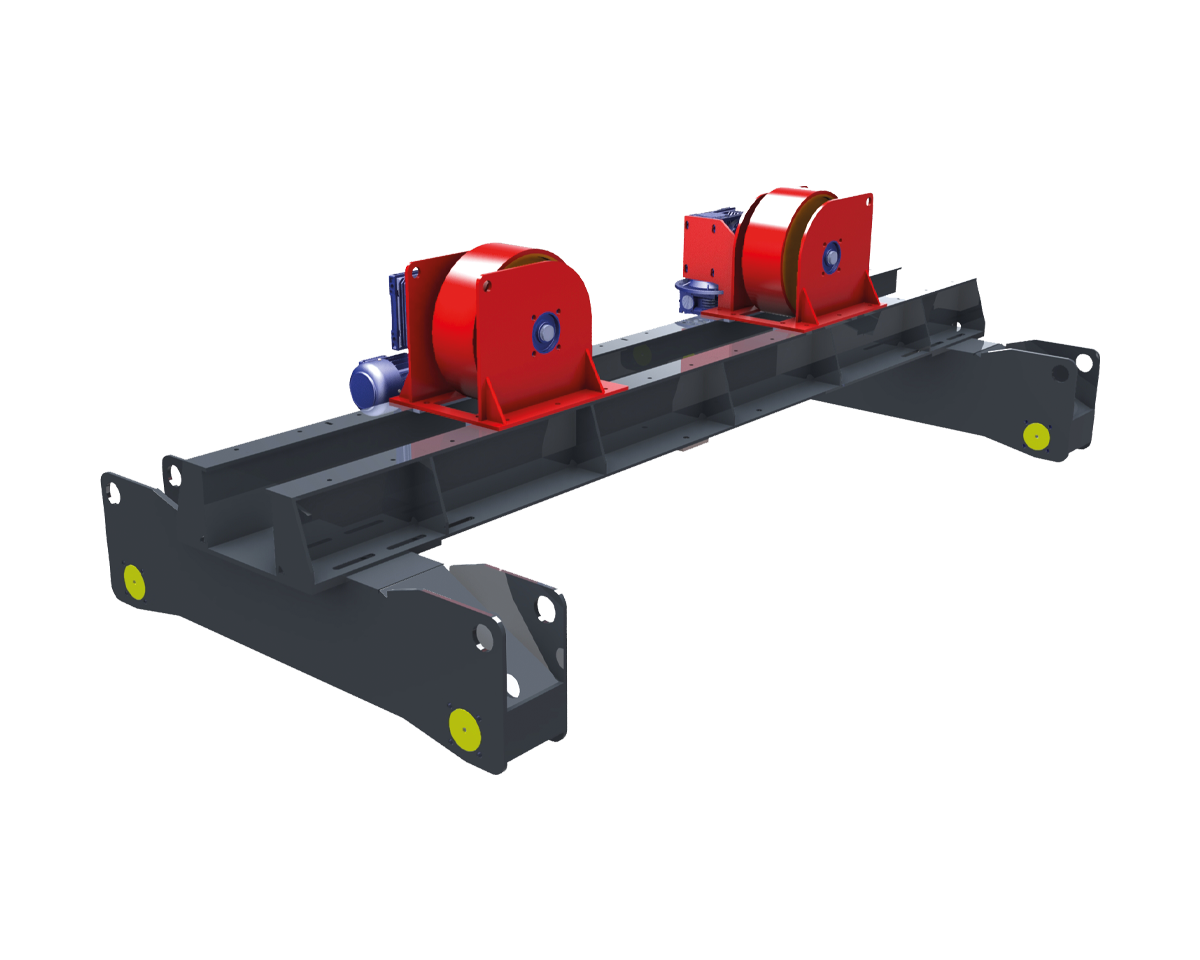

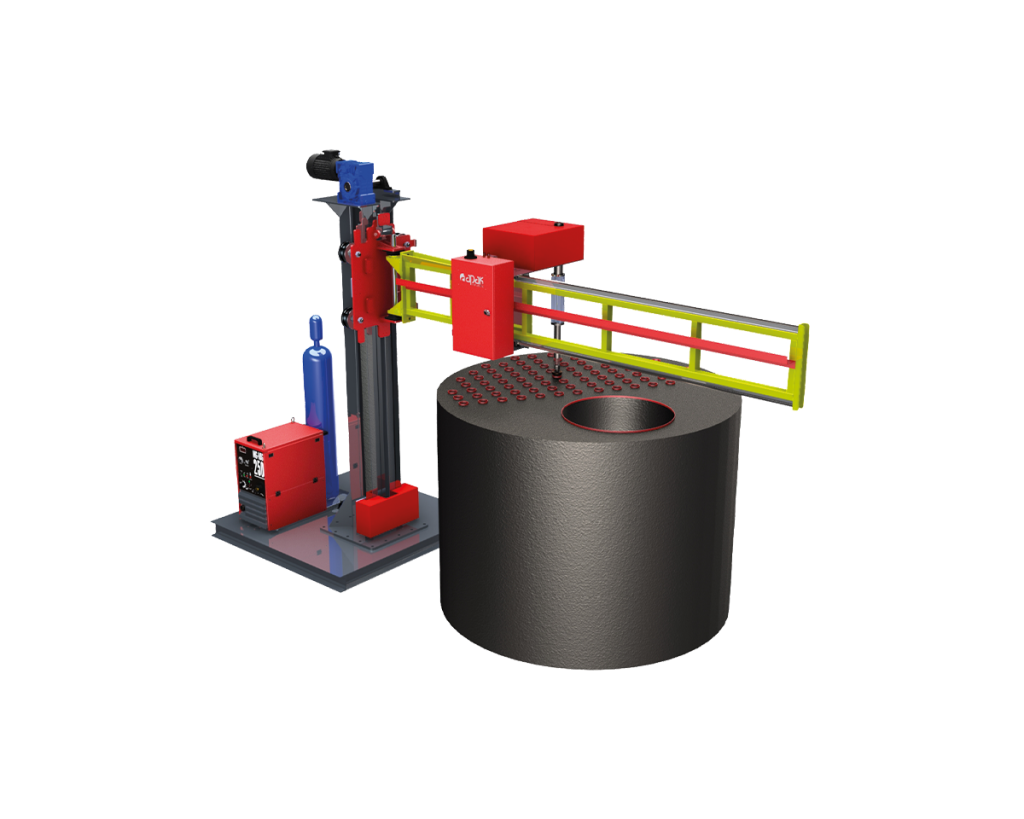

Conventional rotator; It offers an economical and quality solution for quality environmental welding in cases where cylindrical plate diameters are not very variable. It rotates cylindrical parts such as pressure vessels, fuel tanks, and wind turbine towers.

Conventional rotators improve the speed and efficiency during manual and automatic welding and play an important role in steel construction workshops by minimizing crane operation.

The cylindrical plate placed on the converter can be controlled clockwise or counterclockwise via the control panel.

Conventional rotators consist of two units, 1 drive and 1 idle. The number of drive and idle units can be changed according to the application’s needs.

Our product lists include conventional spinners with a capacity of 1 to 150 tons, which are our standard products. Special production can be made up to 500 tons.

If standard conventional type rotators do not meet your production needs, contact us and get information about special rotators we can offer.

- Tanks

- Pressurized containers

- Tower piping

- Boiler

- Silos

- Reactors

- Fuel drums

FEATURES & BENEFITS

Standard Features

- Digital speed indicator on the control panel for monitoring rotation

- Manual diameter adjustments

- Motors with brake

- Adjustable rotating speed

- “PU” roller absorbing shocks and vibrations

- Remote controller with 5-meter cable length

Optional Features

- Bogie Rail Travel system

- Custom roller designs for areas that require high temperature

- Axis Support

- Auto diameter adjustment (motorized)

- Brush Earthing System

- Rail

- Wireless controller system

DOCUMENTS

Conventional Rotators

English Brochure

Automatisches Orbitalschweißen

Deutsche Broschüre

MEDIA

Our team of experts will help you in all situations

You tell about your production problems, we will offer solutions.

01

Tell us about your problems and your goals in manufacturing.

02

We will contact you and provide detailed negotiations.

03

Let us offer you our specially prepared solution suggestions.