DESCRIPTION

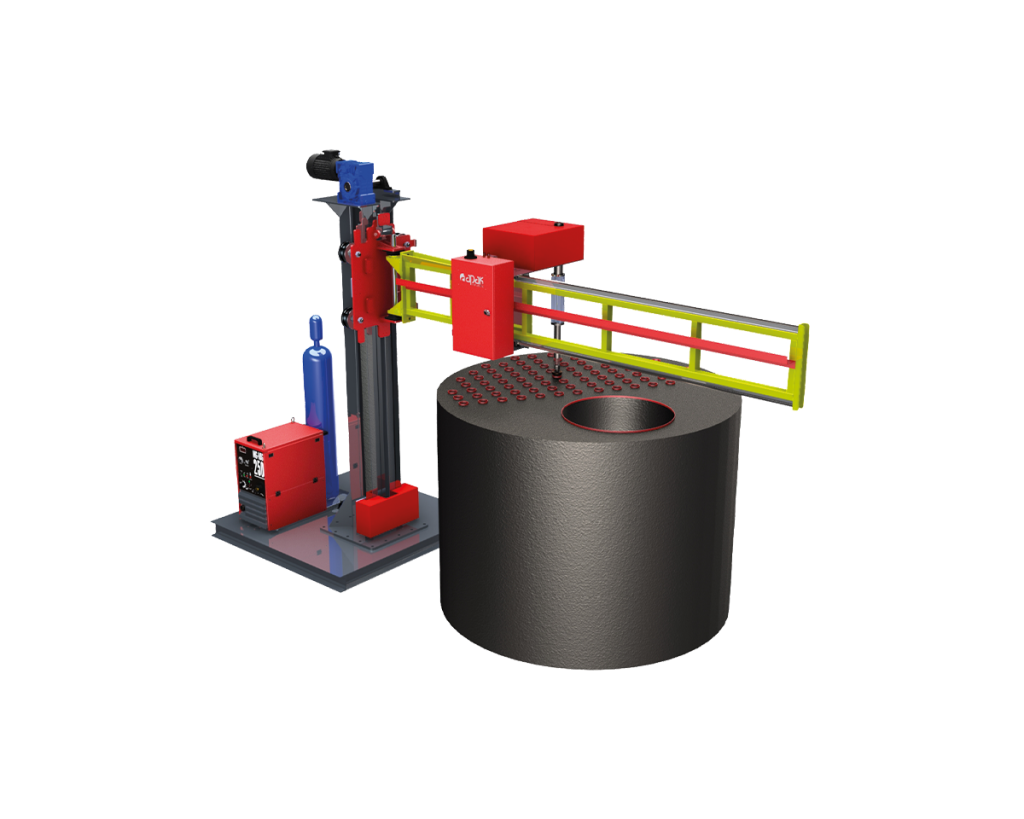

The chair mechanism welding machine is an example of the sectoral welding automation we have designed. It is a system designed for mechanism welding of swivel and gaming chairs.

In cases where standard machinery and equipment cannot meet your production needs, it can be redesigned and produced according to your needs. It can be used for all business lines requiring turntable welding. The systems we design have perfect welding results, reducing the need for time, human labor, and qualified personnel.

GMAW (MIG/MAG) or GTAW (TIG) welding systems can be preferred according to the need.

Contact us for our economical, highly efficient, and user-friendly system recommendations for your products.

- Chair and seat manufacturing

- Pipe flange welding

- Automotive sub-industry

- Productions requiring rotary tables

- GMAW (MIG/MAG)

- GTAW (TIG)

FEATURES & BENEFITS

Application Examples

Engineered for productivity.

- Easy setup and programming

- It can be used with existing GMAW (MIG/MAG) and GTAW (TIG) welding machines

- It can be used with different fixtures

- Ease of use without the need for qualified personnel

- Ability to use conventional power units or Synergic MIG welder

- Systems can be designed and customized for your specific application

- More consistent weld quality and repeatability

Standard Features

- Two-axis torch distance adjustment

- Ability to adjust the rotary welding angle

- Pneumatic compression

- Retractable mirror for different fixtures

- Welding enclosure

Optional Features

- GMAW (MIG/MAG)

- GTAW (TIG)

- Lighting

- Water cooling system

DOCUMENTS

Chair Mechanism Welding Machine

English Brochure

Automatisches Orbitalschweißen

Deutsche Broschüre

MEDIA

Our team of experts will help you in all situations

You tell about your production problems, we will offer solutions.

01

Tell us about your problems and your goals in manufacturing.

02

We will contact you and provide detailed negotiations.

03

Let us offer you our specially prepared solution suggestions.