DESCRIPTION

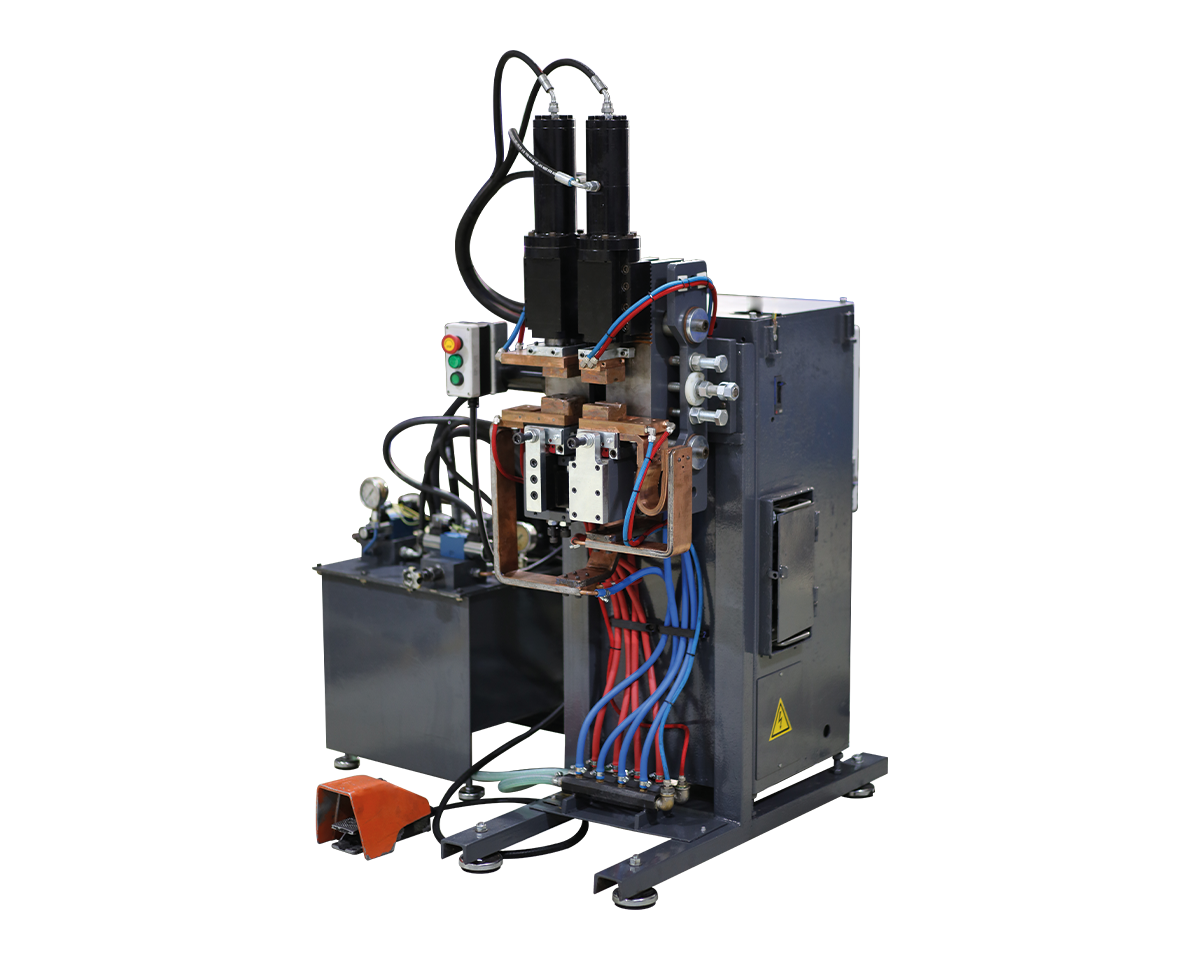

Butt welding machine; It is designed for welding nuts, bolts, and similar parts to shaft and pipe ends by resistance welding method. One of the welding jaws is fixed, and the other is movable on the horizontal axis. The clamping and pressing process is pneumatic or hydraulic, according to need.

Welding jaw has high axis precision by moving on linear bearings. Welding jaws can be adjusted in 3 axes, allowing you to have the axis dimensions you may need in your production. The PLC control system used in the system guarantees excellent repeatable welding results. The welding control unit monitors the required current continuously and controls the joining process according to the current determined during the welding process.

Welding jaws, which can be redesigned according to different sectors and workpieces, can serve every industry needing a butt welding machine with machine power.

You can visit our contact page for more detailed information and requests about the system.

- Automotive

- Aerospace

- Industrial applications

- Metalware production

- Resistance Welding

FEATURES & BENEFITS

Application Examples

Engineered for productivity.

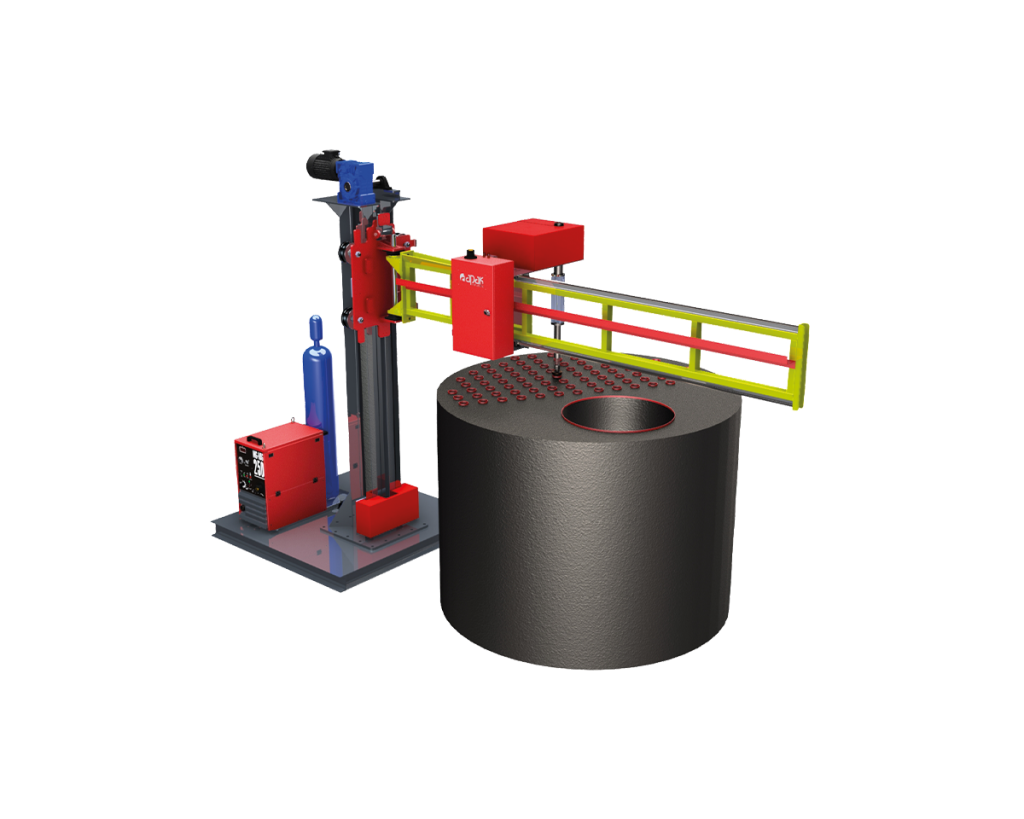

It is a system designed to be used in productions that need mass production. With the 2 fixing jaws on the system, it can make continuous welding by switching between the parts to be welded.

With the optional water cooling system, overheating is prevented during high amperage and long welding times.

With this system, you can continue production by minimizing human labor.

It offers the opportunity to weld pipes and shafts of all types and sizes with the resistance welding method.

Standard Features

- Pulsed welding current

- Starting with the foot pedal

- Pneumatic holding and clamping

Optional Features

- Water cooling unit

- Hydraulic holding and pressing system

- Spot Counter

- Remote control and reporting system

DOCUMENTS

Butt Welding Machine

English Brochure

Automatisches Orbitalschweißen

Deutsche Broschüre

MEDIA

Our team of experts will help you in all situations

You tell about your production problems, we will offer solutions.

01

Tell us about your problems and your goals in manufacturing.

02

We will contact you and provide detailed negotiations.

03

Let us offer you our specially prepared solution suggestions.