DESCRIPTION

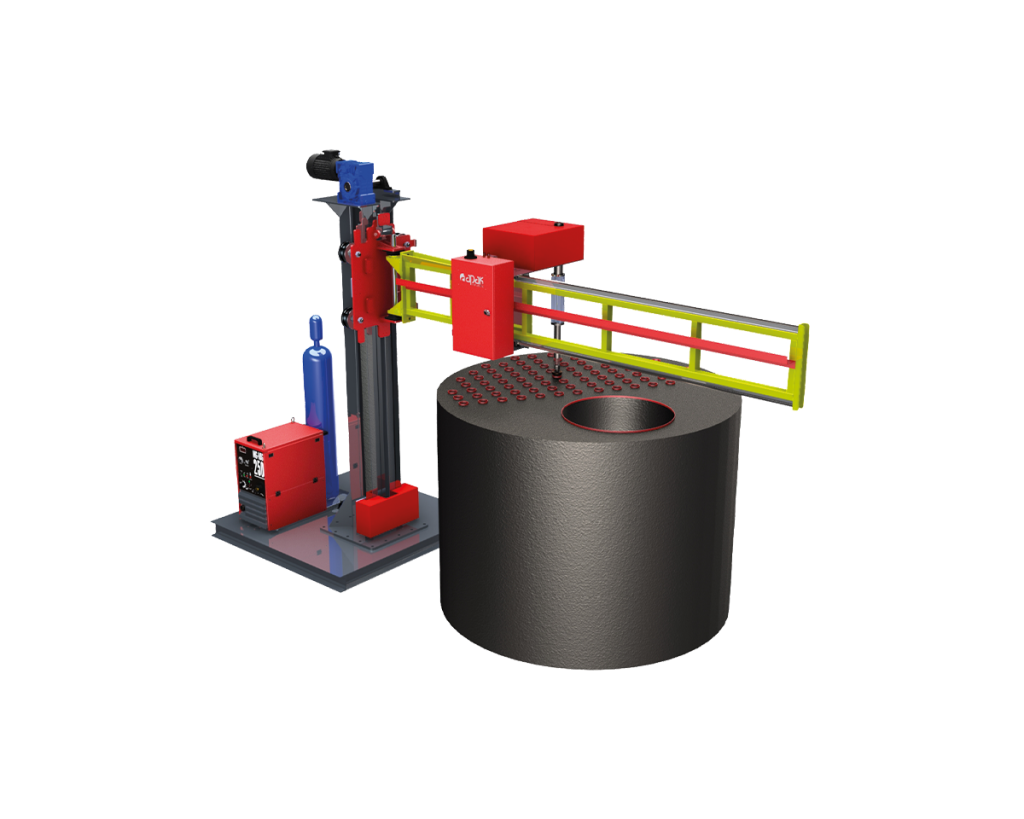

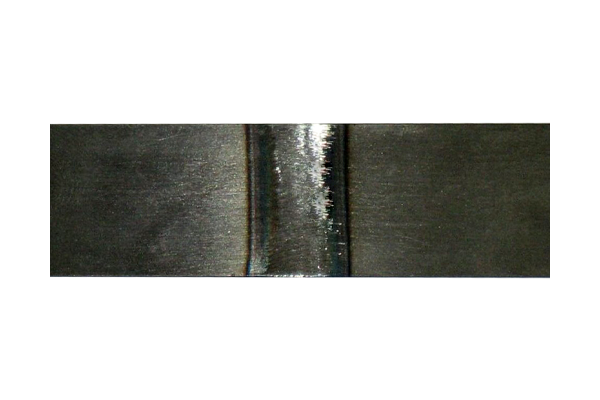

Band Saw Welding Machine from Apak Interwelding is a reliable and economical solution for joining saw bands, steel strips, and band knives. Therefore, it is an essential tool for manufacturers who need precise and durable welding results. The system supports both butt welding and flash butt welding, which increases flexibility in production.

Moreover, the ergonomic design of the APAK-BSW 050 model reduces operator fatigue and simplifies operation. By minimizing manual workload, it allows faster cycles and higher productivity. As a result, manufacturers can lower labor costs while maintaining consistent welding quality.

In addition, the machine can be redesigned to handle different widths and thicknesses. This adaptability makes it suitable for a wide range of applications. For example, whether working with narrow saw bands or larger steel strips, the Band Saw Welding Machine ensures precise alignment and repeatable welds.

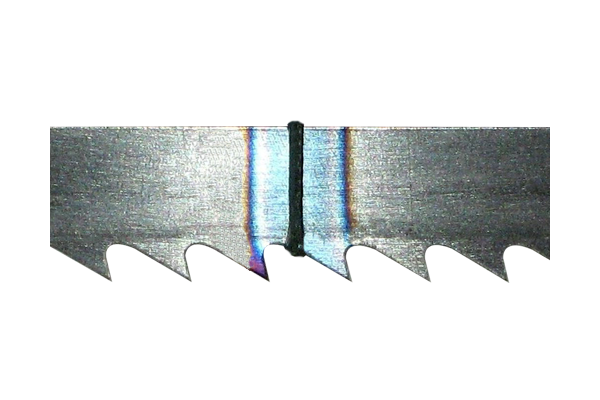

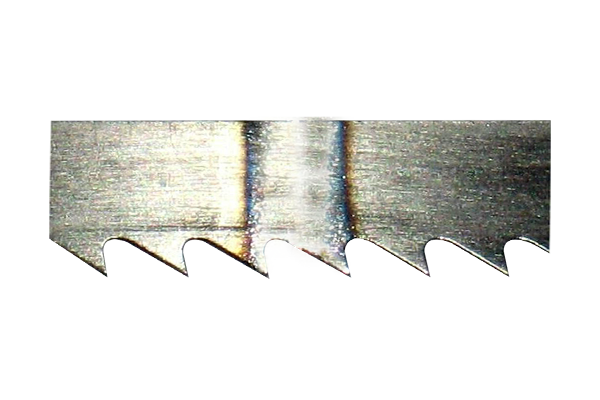

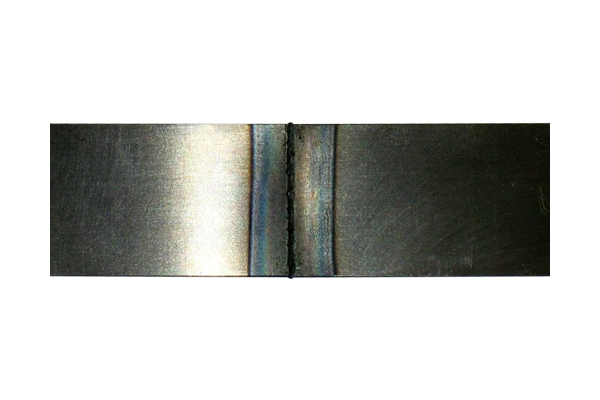

Furthermore, the system’s strong structure and advanced clamping mechanism guarantee stability during welding. This feature reduces errors caused by misalignment and ensures uniform seam quality. Consequently, scrap rates are minimized, and efficiency in production is increased.

The use of butt and flash butt welding eliminates the need for solder, flux, or additional filler materials. Thus, welds remain clean and durable, requiring less post-processing. Another advantage is that the control systems are designed for easy monitoring and consistent results, even during long production runs.

In conclusion, the Band Saw Welding Machine combines ergonomic operation, flexible design, and reliable welding technology. Therefore, it is an ideal choice for industries that demand efficient and economical solutions for saw blade and strip welding. To learn more about the system or to receive a tailored solution, please contact Apak Interwelding.

- Band saws

- Coil joining

- Wire joining

- Vehicle wheel production

- Productions requiring spindle welding

- Resistance Welding

FEATURES & BENEFITS

Application Examples

Engineered for productivity.

Advantages of our welding machines for band knives, steel strips, and saw bands.

- No additional material is required in the welding process

- Machine body and equipment resistant to harsh working environments

- Perfectly aligned weld with precise and wear-free guides

- Variable manual, pneumatic, and hydraulic clamping systems according to the device model to prevent the part from slipping during welding with high-pressure distribution

- The control panel is in a separate cabinet to protect against dirt, dust, and damage.

- Mechanically or pneumatically tensioned spring system for standard welding results

DOCUMENTS

Band Saw Welding Machine

English Brochure

Automatisches Orbitalschweißen

Deutsche Broschüre

MEDIA

Our team of experts will help you in all situations

You tell about your production problems, we will offer solutions.

01

Tell us about your problems and your goals in manufacturing.

02

We will contact you and provide detailed negotiations.

03

Let us offer you our specially prepared solution suggestions.