Apak Group

Unsere

Marken

Apak Group Companies

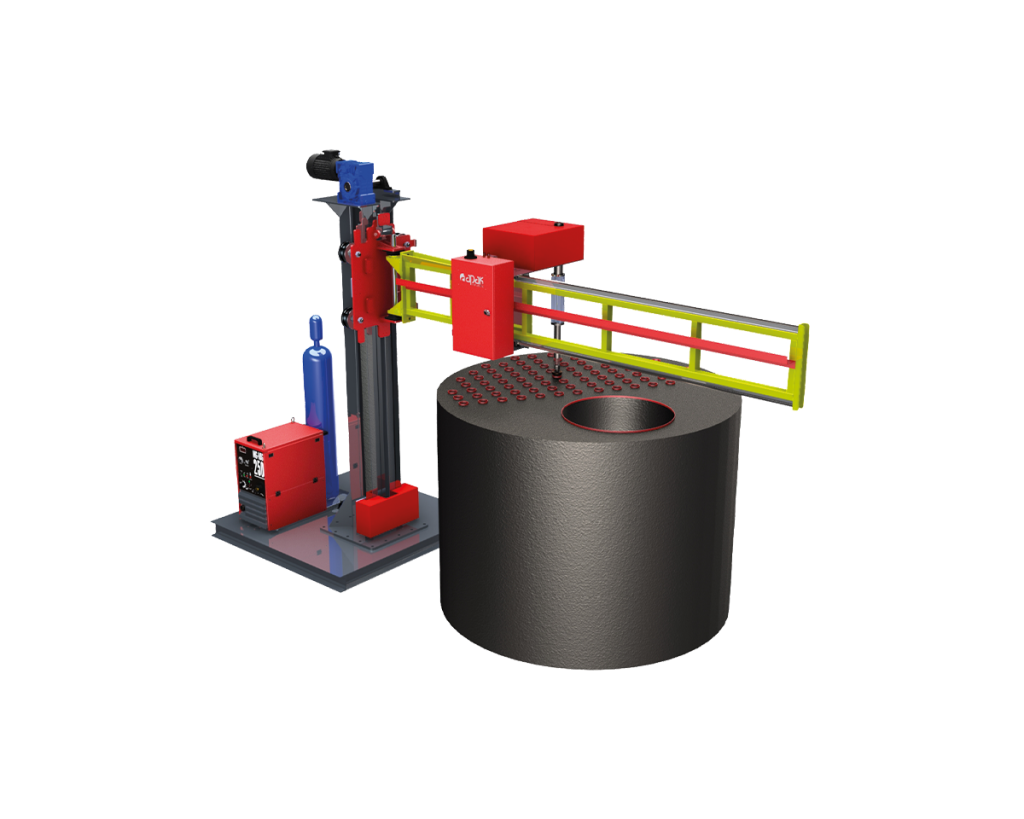

Interwelding

Apak Interwelding specializes in advanced welding automation systems, orbital welding solutions, and custom machine design for industrial production. Since 1972, the brand has delivered reliable, efficient, and CE-compliant welding equipment with integrated Profinet controls and servo-driven axes. From column & boom and rotators to coil joining and clamp forming, Apak Interwelding ensures precision and repeatable welding quality.

Identifying needs

Demands and technical specifications are carefully analyzed through detailed consultations to define the automation welding system your company requires. This ensures a perfect fit for your production process.

Unique Designs

A complete and customized design process is initiated according to the identified needs. Every automation system is engineered with precision, efficiency, and CE/EN compliance in mind.

Manufacturing

The production process is completed with strict quality inspections and mechanical testing to guarantee durable and reliable automation welding equipment.

Assembly and Installation

After production is completed, final assembly and inspection are carried out at the customer’s facility to ensure optimal performance and integration.

Operating and training the System

Machine operators receive practical training and operational instructions to start up the system safely and efficiently during commissioning.

Trading

Apak Trading specializes in industrial procurement, project supply, and technical sourcing for oil, gas, power, and manufacturing industries. The brand ensures on-time delivery, QA documentation, and inspection for all ordered materials. With decades of engineering experience, Apak Trading combines strong supplier relations and logistics expertise to provide complete, reliable, and efficient industrial solutions.

RFQ & Specification Management

Apak Trading manages RFQs, technical clarifications, and document control to ensure accurate procurement aligned with your project’s requirements.

Supplier Evaluation

All suppliers are carefully evaluated for quality, reliability, and certification compliance to guarantee consistent industrial standards.

Packaging & Logistics

Optimized packing and logistics solutions ensure safe and on-time global delivery of all equipment and spare parts.

Inspection & QA Documentation

Every shipment includes QA/QC certificates and inspection reports, ensuring traceability and project documentation compliance.

Global Support & Coordination

With multilingual support and export experience, Apak Trading ensures smooth coordination and complete visibility across your supply chain.

Service

Apak Service provides repair, maintenance, spare parts, and inspection services for all welding and automation systems. Our certified technicians ensure fast troubleshooting, preventive maintenance, and BGV A3 inspections for safety compliance. With original spare parts and on-site commissioning, Apak Service extends machine lifetime and minimizes downtime for uninterrupted production.

Repair & Troubleshooting

Fast and reliable repair services for MIG/MAG, TIG, MMA, Plasma, and automation systems—covering all major welding brands.

Preventive Maintenance

Planned maintenance increases reliability, prevents downtime, and extends the lifetime of your welding systems.

Spare Parts Supply

Original and compatible spare parts available for all welding systems to ensure quick restoration of production.

BGV A3 Inspections

Certified BGV A3 safety inspections for electrical welding systems to maintain compliance and workplace safety.

Operator Training & Support

Professional training and guidance for operators to ensure safe, efficient, and correct machine operation.

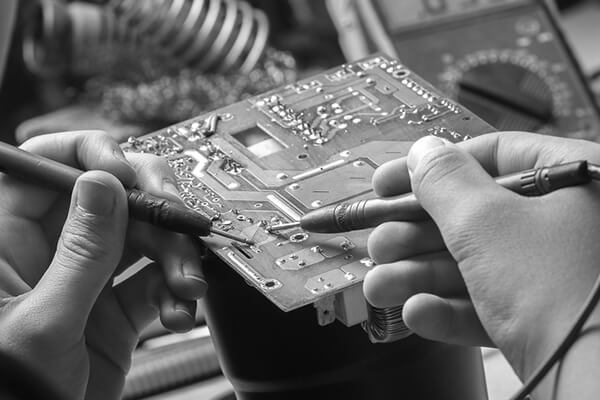

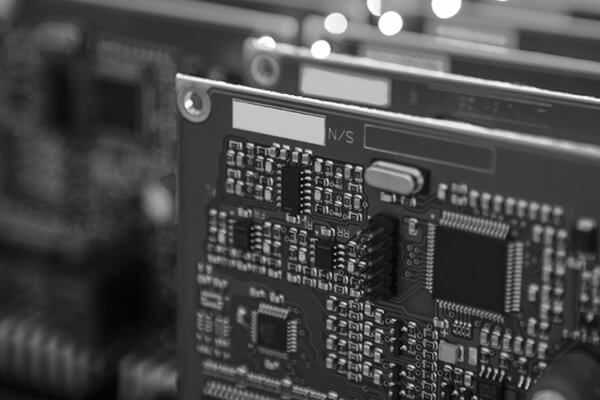

Electronic

Apak Electronic designs and develops LED drivers, power supplies, and custom electronic systems for industrial and lighting applications. Using advanced transformer design, EMC-optimized PCB layouts, and thermal management, Apak Electronic ensures high efficiency, long lifetime, and safety compliance. From prototyping to final validation, every product is built with engineering precision and reliability.

Product Design & Engineering

Innovative electronic design using optimized topologies, reliable components, and efficient PCB layouts for stable power delivery and durability.

Transformer Development

Custom transformer design and magnetic simulation to ensure energy efficiency, low losses, and long-term stability in LED drivers and power modules.

Prototyping & Testing

Rapid prototyping and electrical testing allow optimization of performance, EMC behavior, and thermal management before mass production.

Documentation & Certification

Complete technical documentation and certification processes according to international standards for safe, compliant product delivery.

After-Sales & Support

Continuous technical support, updates, and maintenance assistance to ensure long-term reliability and performance of delivered systems.